trailer cable seal

specification

the lock body is made of metal, the internal steel ball cable-stayed structure, outsourcing plastic ABS.

the color has red, yellow, blue and green four standard colors, can also be customized according to customer requirements of any other color.

the lock body surface using hot stamping or laser printing marks, barcodes and codes.

steel wire diameter φ1.8mm, length according to customer demand at will.

tensile force can reach F≥300㎏. Effective temperature range -40℃ to 110℃

the standard packaging is 100 bags per box, 20 bags per box.

Heavy-duty trailer cable seals are an indispensable physical security tool in modern logistics and supply chain security. Designed specifically for sealing containers, trailers, and cargo doors, this pull-type security seal combines high-strength steel cable with a robust lock body, providing a reliable, intuitive, and legally binding tamper-proof solution. This product aims to provide B2B buyers, including logistics companies, freight forwarders, shipping companies, and large manufacturers, with a critical link in ensuring asset integrity during cargo transportation, effectively preventing theft, unauthorized entry, and cargo swapping risks, and ensuring end-to-end

traceability and security of the supply chain.

Core Product Features

1. Superior Mechanical Strength and Vandal Resistance

The core value of this product lies in its superior physical protection capabilities.

High Tensile Strength Steel Cable: Utilizing multi-strand, galvanized high-strength steel cable as the sealing line, typically with a diameter between 2.0mm and 3.0mm, it provides a tensile strength of up to 1500N to 2500N or more. This design effectively resists common vandalism methods such as shearing with pliers or violent pulling.

Robust Lock Body Structure: The lock body is typically constructed from a metal outer shell or engineering plastics (such as ABS) encasing a metal core. It employs a one-time locking mechanism (such as a spring ball or ratchet mechanism), ensuring that once the cable is tightened and locked, it cannot be pulled out or opened without causing permanent damage.

Clear Evidence of Tampering: Any successful attempt at sabotage will leave indisputable traces—either the cable is cut, or the lock body is crushed or severely deformed. This obvious physical damage provides conclusive evidence for subsequent audits and liability determination.

2. Excellent Environmental Resistance and Durability: Considering the complexity of transportation environments, our trailer safety seals are designed to withstand harsh conditions.

Weather and Corrosion Resistance: The galvanized coating of the cable and the rust-proofing treatment of the lock body ensure that the product maintains its performance in humid, salt spray (marine environments), and various weather conditions, preventing accidental breakage due to corrosion.

Wide Temperature Range Adaptability: Maintains its mechanical properties and locking function within a temperature range of -40°C to +80°C, suitable for global shipping routes from extremely cold regions to high-temperature ports.

3. Efficient On-Site Operation and Identification Management: The product design fully considers the efficiency and manageability of logistics operations.

Tool-Free Quick Sealing: Operators simply thread a steel cable through the bolt hole, insert it into the lock body, and tighten it to complete a one-time secure seal. The process is simple and quick, requiring no special training or tools.

Comprehensive Traceability Identification: The lock body surface provides ample area for laser engraving or embossing unique serial numbers, company logos, barcodes, or QR codes. This enables individual tracking of each seal and its binding to shipping documents, greatly enhancing supply chain visibility and security management.

Main Application Scenarios

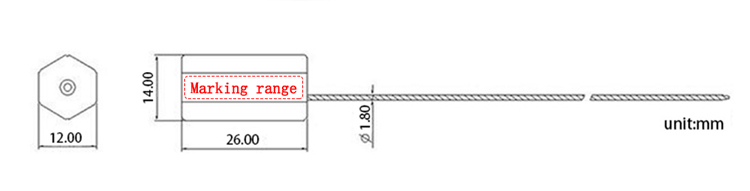

Number | S-001 |

Material | ABS covered+steel lock body+galvanized steel wire |

Lock size | 26*14*12mm |

Tension | 980N |

Lenght | Standard line length 240mm, can be customized |

Diameter | 1.5mm/1.8mm or cuatomized |

Shell color | yellow,red,blue,green,white,orange and so on |

Printing type | Laser printing or hot stamping |

Marking contents | Company name, LOGO, text, number, QR code, bar code |

Application | containers, trailers, oil tankers, ships, tailfreight, logistics freight, safes, lockers, etc. |

Customize or not | Provide customized services |

Sample service | Free sample |

Quality testing | Provide quality inspection report |

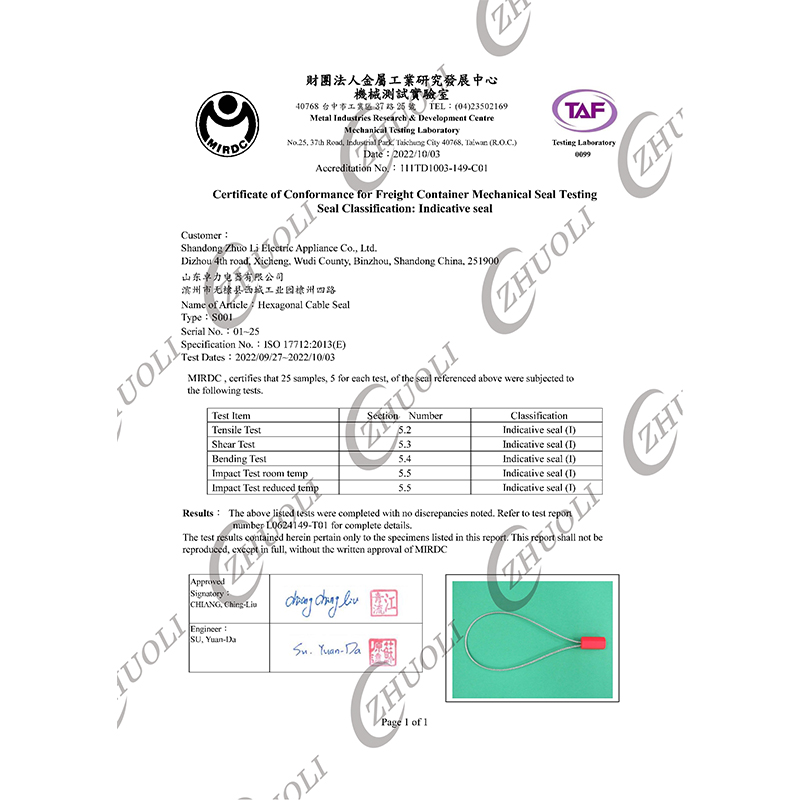

Quality inspection certificate

Products through the quality inspection system, in line with the safety seal standards(ISO17712)

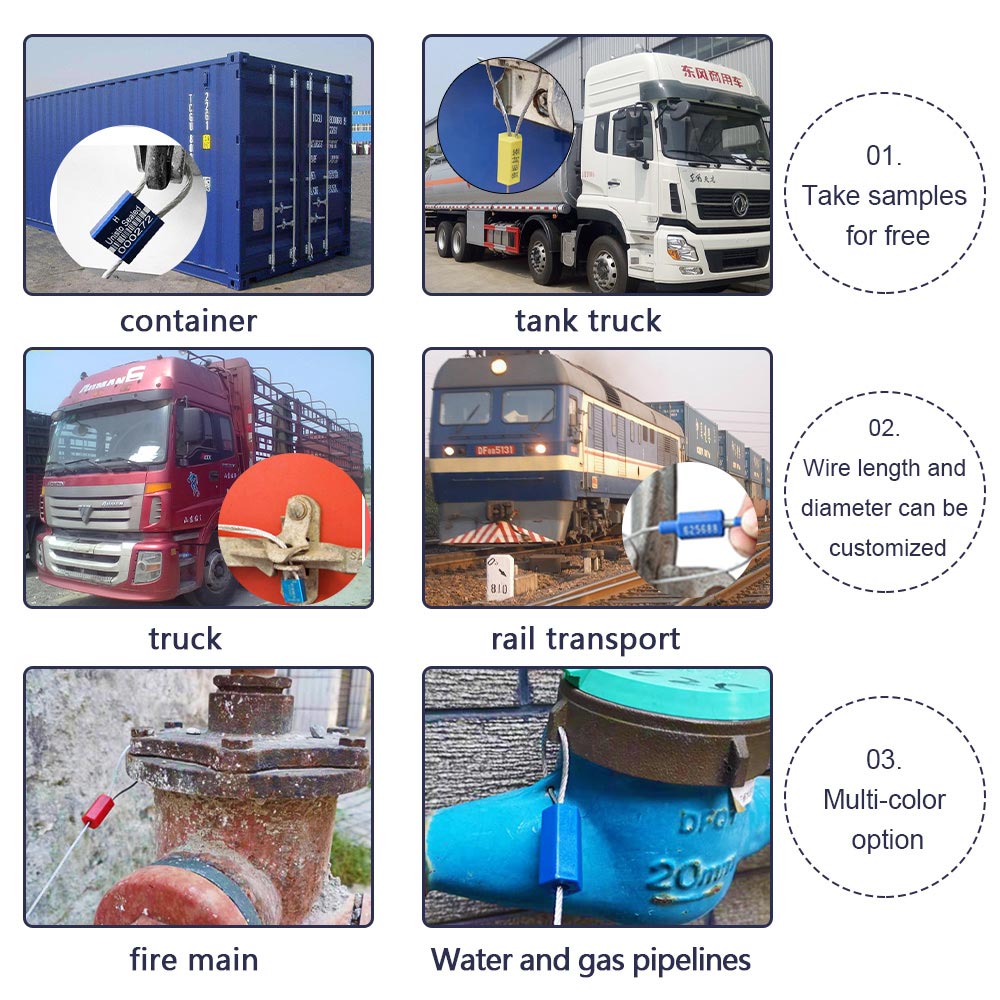

Main Application Scenarios

Heavy-duty trailer cable seals are a universal standard for ensuring the safety of land, sea, and multimodal transport. Typical applications include:

International Shipping Container Sealing: As a high-security mechanical seal conforming to ISO 17712 standards (a declaration based on actual product certification is recommended), it is used to seal the door locks of ocean-going containers, serving as a crucial document for the integrity of goods during international trade.

Road Freight Trailer and Trailer Sealing: Used to seal the door locks of box trucks, flatbed trailers, and refrigerated trucks, ensuring the safety of goods during long-distance or short-distance road transport and preventing unauthorized opening at stops or rest areas.

Railway Freight and Air Freight Containers: Suitable for sealing railway freight cars and air cargo containers (ULDs), meeting the safety and regulatory requirements of various transport modes.

Warehouse and Logistics Park Security: Used to seal temporary storage areas, high-value cargo storage units, or goods awaiting inspection, serving as a physical means of internal security control and responsibility allocation.

Energy and Chemical Industries: Used for sealing tanker truck covers, chemical transport pipeline valves, etc., ensuring the safe and secure transport of hazardous materials during transit and transshipment.

Application:

containers, trailers, oil tankers, ships, tailfreight, logistics freight, safes, lockers, etc. Enterprise product inspection, packaging bucket packaging work to use wire seal

Product packaging: 100pcs per bag,1000pcs /Carton(Box size:38*28*21cm/32*23*19cm)

Frequently Asked Questions (FAQ)

1. What does the tensile strength data (e.g., 2200N) of this steel cable seal specifically mean? What kind of damage can it withstand in practice?

Tensile strength (in Newtons, N) represents the maximum force the seal can withstand before breaking axially. 2200N is approximately equal to 224 kgf. This means that without damaging the lock body structure, a tensile force exceeding 224 kg is required to break the steel cable. In practical scenarios, this effectively resists cutting attempts using handheld wire cutters or forceful prying with tools, forcing attackers to use large wire cutters or abrasive tools, which generates significant noise, is time-consuming, and leaves very obvious damage marks.

2. What kind of custom markings can we implement on the seal? How does this help with logistics management?

We offer comprehensive customization services. You can request embossing or laser engraving of: 1) a unique serial number, ensuring one code per item for easy database tracking; 2) company name and logo, enhancing brand recognition and anti-counterfeiting; 3) scannable barcodes or QR codes, enabling rapid scanning and electronic recording during sealing and verification processes through integration with Transportation Management Systems (TMS) or Warehouse Management Systems (WMS), significantly improving the efficiency and accuracy of logistics security management.

3. What are the main advantages of steel cable seals compared to disposable plastic seals or bolt seals?

Compared to standard plastic seals, steel cable seals offer overwhelming advantages in physical strength and vandal resistance, providing a higher level of protection for high-value goods or high-risk transportation routes. Compared to heavy-duty bolt seals, steel cable seals are more flexible, adaptable to locking points of different angles and shapes, and typically offer faster sealing speeds and more competitive costs, making them the preferred solution balancing extremely high security and operational efficiency.

4. Does using your seals comply with international customs or industry security standards? Our trailer and container cable seals are designed and manufactured to internationally recognized high standards. For specific customer needs, we can provide products that meet or exceed the relevant ISO (International Organization for Standardization) recommended standards for security seals. We recommend selecting product models with relevant certifications or test reports based on your specific trade routes and customer requirements. As a responsible security seal supplier, we can provide relevant performance test data to support your compliance audits.