custom cable seals

Product advantages

Most of our cable seals are developed of galvanized metallic airplane cable, which will unravel upon cutting. This attribute minimizes unauthorized reuse of the seal.

Our cable seals consist of these delivered factors and benefits:

1. Tension type structure, easy to operate;

2. Zinc alloy + galvanized steel wire, wear-resistant and anti-corrosion;

3. Hot stamping or laser printing, clear handwriting and bright color;

4. Customization service (color, material, LOGO, wire diameter and length);

All of our cable seals are manufactured in offerings which are CTPAT compliant.

Cable seals are lengthy lasting and supposed for larger protection applications. They are reachable in special cable diameters and lengths for use in greater than a few applications.

Our 3.5mm and 5.0mm cable seals are compliant with ISO 17712:2013 and are rated as a immoderate safety seals.

Custom Cable Seals: Your Ultimate Tailored Solution for Tamper-Evident Security

In an era where supply chain integrity and asset protection are paramount, a one-size-fits-all approach to security is insufficient. Custom cable seals provide a sophisticated, tamper-evident solution engineered to meet the specific requirements of your operations. Unlike generic security seals, these are designed from the ground up to incorporate your unique specifications—from dimensions and materials to integrated branding and serialization. They serve as a critical component in safeguarding high-value cargo, utility meters, transportation containers, and sensitive equipment worldwide. By investing in customizable tamper-proof seals, your organization not only enhances physical security but also reinforces brand identity and operational control throughout the logistics chain.

Strategic Advantages of Customization

Choosing to implement bespoke security sealing solutions offers a range of strategic benefits that extend far beyond basic containment, delivering tangible ROI through enhanced security, efficiency, and brand presence.

Enhanced Security Through Exclusive Design

A primary advantage of custom cable seals is the inherent security provided by a unique design. Customized locking mechanisms, cable diameters, and head configurations create a proprietary security profile that is extremely difficult for unauthorized parties to replicate or defeat. This exclusivity acts as a powerful deterrent against tampering and theft, ensuring a high-security seal for logistics that is uniquely yours.

Branding & Immediate Authentication

Transform a simple security device into a powerful brand ambassador. Your logo, company name, specific color codes, and sequential or barcoded serial numbers can be permanently molded or laser-marked onto the seal body. This custom branded security seal allows for instant visual identification, streamlines audits, and enhances accountability by making each seal traceable directly to your organization.

Optimized Fit for Specific Applications

Standard seals may not fit unusual asset shapes or meet specific environmental challenges. Customization allows you to specify the exact cable length, thickness (diameter), and material composition (e.g., high-tensile steel with a PVC or nylon coating) to ensure a perfect, secure fit for your assets, whether it's a valve, a meter box, or a specialized container. This ensures reliable sealing solutions for harsh environments.

Operational Efficiency & Supply Chain Control

Bulk ordering of tailored cable and lock seals with pre-programmed, unique serial numbers integrates seamlessly into inventory and tracking systems. This simplifies management, reduces the risk of using counterfeit or inferior seals, and provides a clear, auditable trail—a critical feature for industries like pharmaceuticals, aerospace, and high-value manufacturing where compliance and provenance are non-negotiable.

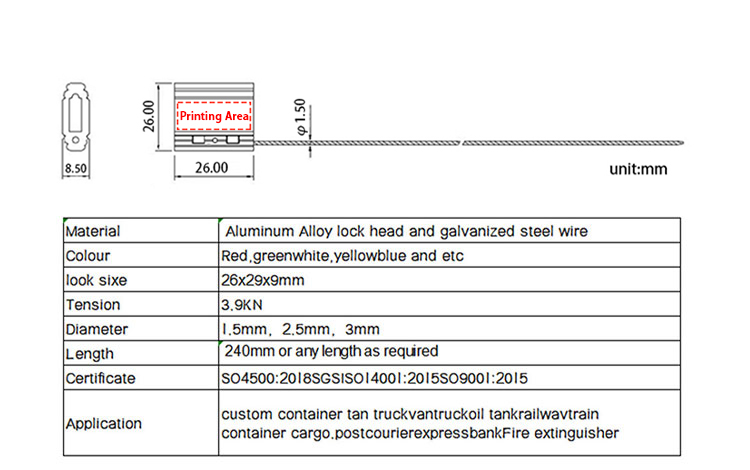

Product Characteristics & Technical Specifications

Our custom cable seals are manufactured to the highest standards, offering a blend of durability, security, and adaptability.

Core Cable: Constructed from galvanized or stainless steel, available in various tensile strengths and diameters (e.g., 2.0mm, 3.0mm) to balance flexibility with cut resistance.

External Sheath: A durable PVC or nylon coating protects the internal cable from corrosion, abrasion, and weather, while also allowing for color customization.

Locking Mechanism: The seal head typically houses a high-security, self-locking mechanism (such as a ball-lock or uni-directional barbed design). Once the cable tip is inserted and pulled taut, it cannot be removed without causing irreversible, visible damage—providing clear tamper-evident protection for assets.

Custom Marking: We utilize permanent molding or precision laser etching to apply your branding and sequential alphanumeric, barcode, or QR code numbering. This ensures markings are legible and resistant to fading or wear.

Diverse Industry Applications

The versatility of custom cable seals makes them indispensable across a broad spectrum of industries requiring verifiable security.

Logistics & Transportation: Securing shipping containers, truck doors, and air cargo. Custom seals for shipping containers are critical for maintaining the integrity of international shipments and complying with C-TPAT, AEO, and other security protocols.

Energy & Utilities: Locking electric meters, valve boxes, and pipeline access points to prevent unauthorized access, tampering, or theft of services.

Retail & Manufacturing: Securing high-value displays, securing transported goods on roll cages, and protecting in-transit electronics and apparel.

Aviation & Aerospace: Sealing sensitive equipment panels, toolboxes, and cargo holds where security and audit trails are mandatory.

Waste Management & Chemicals: Ensuring the security of hazardous material containers during transport and storage.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for developing and receiving an order of custom cable seals?

The timeline varies based on the complexity of the design. For a new custom design, the prototyping and mold creation phase typically takes 8-10 weeks. Once the prototype is approved, production for a standard bulk order usually requires an additional 4-6 weeks. We offer expedited services for urgent requirements and maintain stock programs for repeat orders of bespoke security sealing solutions.

Q2: What is the minimum order quantity (MOQ) for a custom design?

To make the custom tooling and production process cost-effective, we generally require an MOQ. This quantity varies but is typically in the range of 10,000 to 50,000 units, depending on specifications. We encourage a collaborative discussion to find a volume that aligns with your security needs and budget, offering the best value for your tailored cable and lock seals.

Q3: How do the security levels of your custom cable seals compare to standard options?

Our custom cable seals allow you to engineer a higher security level by default. You can specify thicker cables, harder steel grades, and more complex locking mechanisms than those commonly found in generic, off-the-shelf products. This results in a seal with superior pull-apart and cut resistance, providing tamper-evident protection for assets that meet or exceed industry-specific standards.

Q4: Can you help us design a seal if we only have a general concept?

Absolutely. Our engineering and design teams are experts in developing effective customizable tamper-proof seals. We will work closely with you to understand your application, security threats, and operational environment, translating your concept into a functional and manufacturable design. We provide detailed drawings and prototypes for your evaluation before full-scale production begins.