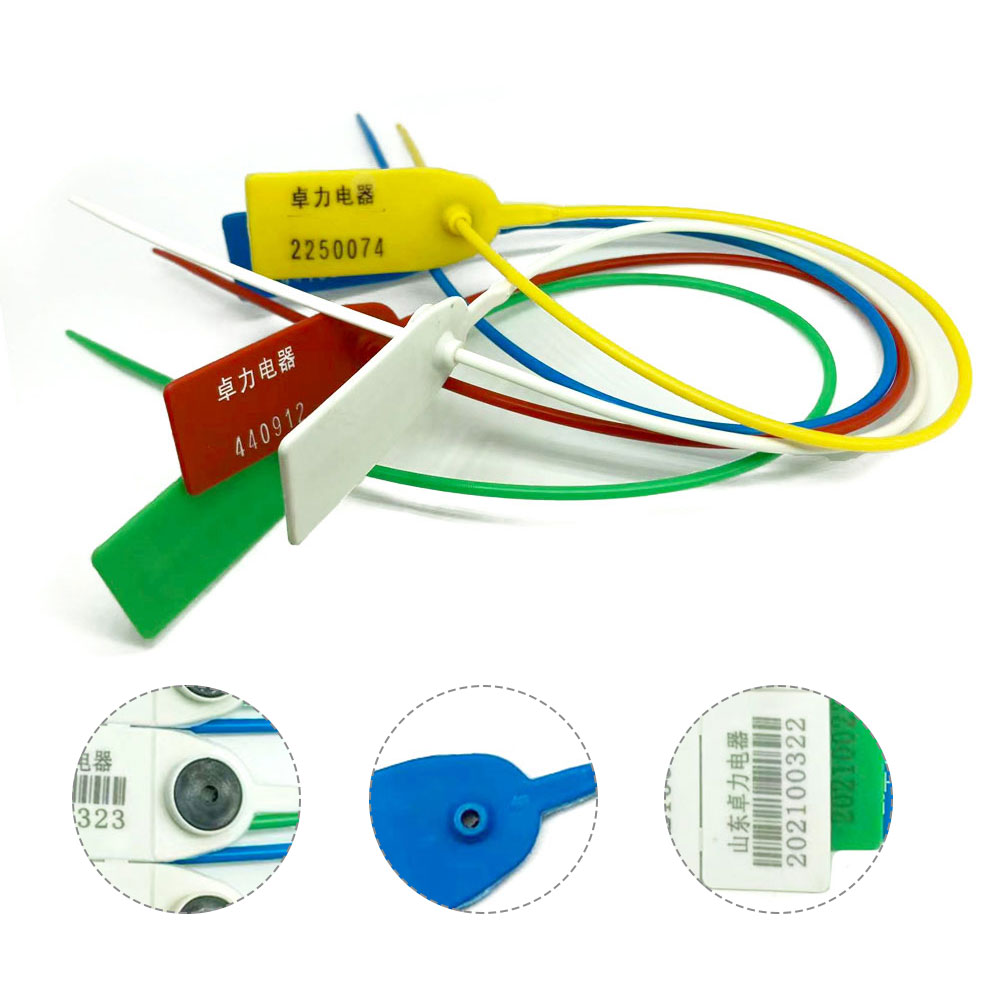

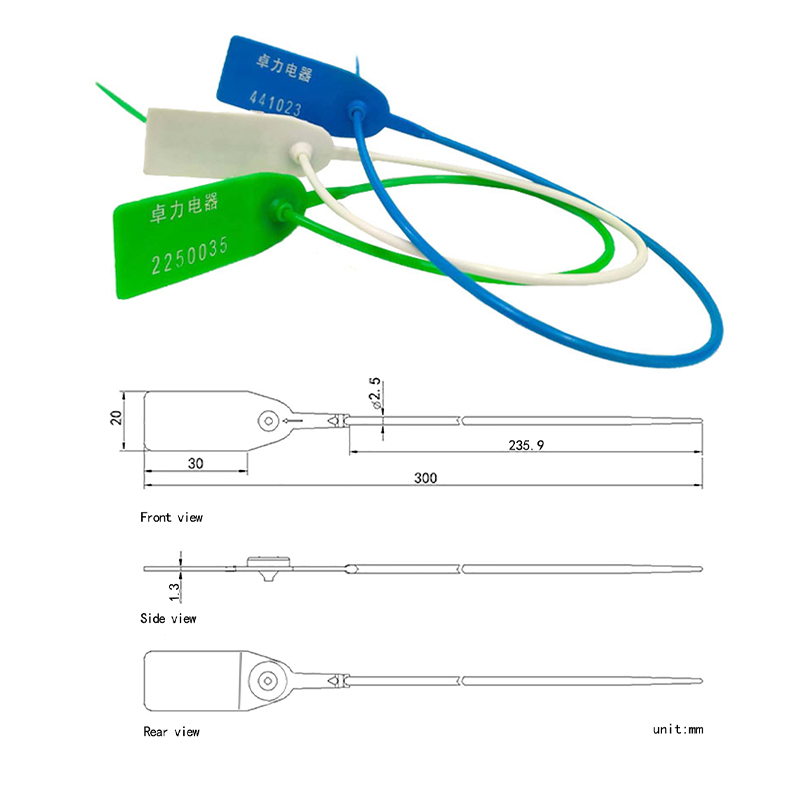

Plastic Safety Seal

Plastic Safety Seal is an adjustable seal and can be used in many one-of-a-kind conditions, in specific in any utility to guard cargo at some stage in transport and inter-modal freight.

With regard to tension plastic seals, one of the ones we can offer is the flat one. The flat seal is suitable for bags and large sacks.

We usually print them using the most advanced laser printing technology, but we can also print plastic seals by hot stamping technology.

Plastic Safety Seals: Your First Line of Defense for Tamper-Evident Security

In an interconnected global economy, the integrity of goods in transit and the security of fixed assets are paramount for business success. Plastic Safety Seals have emerged as an indispensable tool for companies worldwide, providing a simple, cost-effective, and highly reliable solution to deter theft, prevent tampering, and ensure accountability. This professional product introduction will explore the defining characteristics, multifaceted advantages, and diverse applications of high-quality Plastic Safety Seals, demonstrating why they are a critical component in modern security and logistics protocols.

Defining Features of a High-Quality Plastic Safety Seal

A superior Plastic Safety Seal is engineered for performance and reliability, not just as a simple lock. Key features distinguish professional-grade seals from their generic counterparts.

Robust Tamper-Evident Mechanism

The core function of any tamper evident seal is to provide clear, irreversible proof of interference. Our seals are manufactured with a precision-engineered locking mechanism within the head. Once the strap is inserted and pulled tight, it cannot be retracted without causing catastrophic failure to the seal body or strap. This tamper-proof design ensures that any unauthorized access attempt leaves behind unambiguous evidence.

Durable Material Construction

Our Plastic Safety Seals are typically injection-molded from high-strength, engineering-grade plastics such as ABS, Nylon, or Polycarbonate. These materials are selected for their:

Impact Resistance: Withstands physical knocks and drops during handling.

Environmental Resilience: Resists corrosion, moisture, UV exposure, and a wide range of temperatures, making them suitable for both indoor and outdoor use.

Consistent Performance: Ensures reliable locking and breaking strength across all production batches.

Unique Identification for Enhanced Traceability

Beyond basic security, many of our seals are available as numbered plastic seals or barcoded plastic seals. Each seal is marked with a unique, sequential number or a scannable barcode/QR code. This allows for precise tracking in digital systems, linking a specific seal to a specific shipment, asset, or meter, thereby creating an auditable trail.

Plastic Safety Seal with metal locking insert. Prevents the possibility of tearing off the label. Pull-tight plastic seals. Fast and secure application. Metal locking insertion and prevention of torn off labels without easy removal.

Tangible Advantages for International B2B Buyers

Implementing a Plastic Safety Seal system delivers immediate and measurable benefits to your operation's bottom line and operational efficiency.

Cost-Effectiveness and High ROI

Compared to metal seals, Plastic Safety Seals offer an exceptional balance of security and affordability. Their low per-unit cost makes it feasible to secure a high volume of assets without significant expense, while their effectiveness in preventing loss provides a substantial return on investment.

Operational Efficiency and Simplified Audits

The application of light-duty security seals is quick and requires no special tools. This streamlines shipping, warehousing, and inspection processes. For numbered plastic seals, auditors and inspectors can rapidly verify integrity against a log, drastically reducing check times and simplifying compliance reporting.

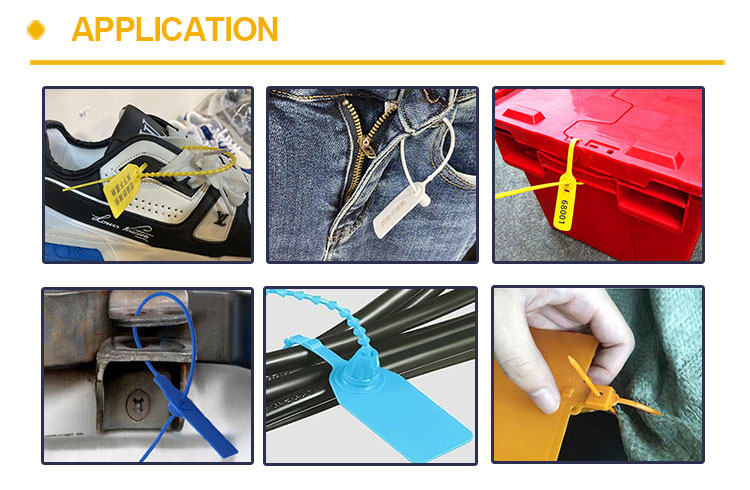

Versatility Across Industries

The simple yet effective design of the Plastic Safety Seal makes it adaptable to a vast array of applications. This versatility means businesses can standardize their security protocols across multiple departments, reducing complexity in procurement and training.

Diverse Application Scenarios

The utility of Plastic Safety Seals spans numerous sectors, proving their value as a universal security solution.

Security Seal Production Pricess:Raw Meterial-Injection Molding-Steel Plate installation-Steel Plate Fixation-Laser Printing-Package

Logistics and Transportation

Cargo Security: Sealing truck doors, shipping containers, and air freight pallets to prevent pilferage during transit.

Inventory Integrity: Securing individual boxes or crates within a larger shipment for enhanced chain-of-custody.

Storage: Security Seals should be stored in their original boxes, protected from direct sunlight and chemical fumes. Store at 22°C/50% RH. Typical shelf life of seals made of PP and PA is approx. 12 months from the date of manufacture. Nevertheless, please do not order quantities longer than one year.

Frequently Asked Questions (FAQ)

Q1: What is the tensile strength of your Plastic Safety Seals, and why does it matter?

A: Tensile strength, the force required to break the seal, varies by model, typically ranging from 50 to over 250 pounds. Selecting a seal with appropriate tensile strength is critical; it must be high enough to resist accidental breakage but also provide a clear break if tampering is attempted, fulfilling its role as a tamper evident seal.

Q2: Can these seals be customized?

A: Absolutely. We specialize in producing custom plastic security seals. You can have your company logo, name, specific color codes, and sequential numbering or barcodes molded directly onto the seal for enhanced branding, authentication, and traceability.

Q3: Are Plastic Safety Seals reusable?

A: No. By design, they are single-use, disposable devices. The tamper-evident mechanism is destroyed upon removal, which is fundamental to their security function. Attempting to reuse them would completely compromise their integrity.

Q4: How do they compare to metal seals?

A: Plastic Safety Seals are generally considered light-to-medium-duty security. They are more cost-effective, lighter, and resistant to corrosion compared to metal seals. For high-security applications like international shipping containers requiring ISO 17712 certification, heavy-duty metal bolt seals are the standard. However, for the vast majority of internal logistics, retail, and utility applications, plastic seals offer the perfect blend of security and value.