Numbered Plastic Security Seals

Numbered plastic security seals are devices designed to provide tamper-evident security for various applications. They are commonly used in industries such as transportation, logistics, healthcare, and more, to ensure the integrity of items, containers, or packages during storage and transit. These seals are made from durable plastic materials and are equipped with unique serial numbers or codes that make them traceable and help in detecting unauthorized access.

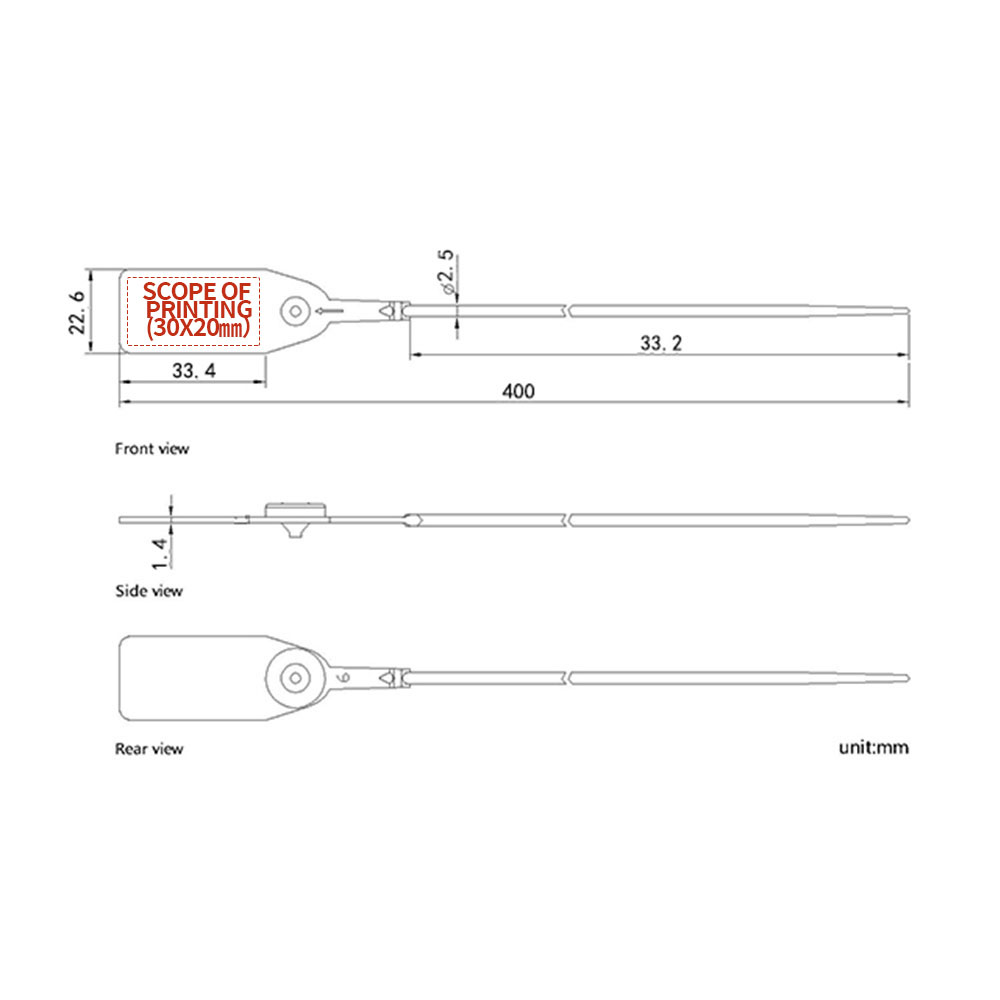

specification:300/400mm

Feature:This product adopts one-time injection molding process, fixed sealing, safer to use.

Marked Price:30*20mm

Seal Marking:Depending on the customer's different needs, we can print running numbers, logos, units, dates, serial numbers, barcodes and other required contents on the labels.

OEM/ODM: Accept OEM and ODM order

Numbered Plastic Security Seals: A Comprehensive Guide for B2B Buyers

In today's complex global supply chains, ensuring the integrity of goods during storage and transit is paramount. Numbered Plastic Security Seals have emerged as a critical tool for businesses seeking reliable, cost-effective, and tamper-evident security solutions. These durable devices provide a visible guarantee of integrity, making them indispensable in industries ranging from logistics and transportation to retail and healthcare. Each seal is distinguished by a unique serial number, enabling precise tracking and creating a robust audit trail. For international B2B buyers, understanding the features, applications, and technical specifications of these numbered plastic security seals is essential for optimizing security protocols and mitigating risks associated with unauthorized access.

Industry Applications and Critical Importance

The versatility of numbered plastic security seals makes them suitable for a wide array of sectors. In transportation and logistics, they are the first line of defense, used to secure cargo containers, truck doors, and air freight. The unique numbering allows logistics managers to track which seal was assigned to which shipment, simplifying accountability. The retail industry relies on them to secure high-value merchandise in display cases or to seal totes during internal transfers, preventing internal shrinkage. In healthcare and pharmaceuticals, these tamper-evident seals are vital for ensuring that sensitive materials and samples have not been compromised, a non-negotiable requirement for regulatory compliance. Furthermore, they are widely used in cash-in-transit bags, election ballot boxes, and utility meters, proving their utility across the board.

Key Features and Technical Advantages

The effectiveness of numbered plastic security seals is rooted in their thoughtful design and construction. B2B buyers should prioritize suppliers whose products offer the following key features:

Durable Plastic Materials: High-quality seals are typically manufactured from engineered thermoplastics like ABS or polypropylene. These materials offer excellent resistance to impact, weathering, UV radiation, and corrosive elements, ensuring the seal remains intact and legible through demanding supply chain conditions.

Tamper-Evident Locking Mechanism: The core of the seal's security is its one-time-use locking mechanism. Once the pin or strap is fully inserted into the body, it locks permanently. Any attempt to remove it by force will result in visible breakage, typically leaving the pin trapped inside or fracturing the body. This provides clear, irreversible evidence of a security breach.

Unique Sequential Numbering: Each seal is marked with a unique, non-repeating number. This serialization is the cornerstone of traceability. It allows for precise record-keeping, where the seal number is logged against a specific shipment, container, or asset. This system deters theft and makes it easy to identify where and when a breach occurred.

Custom Marking Options: Beyond sequential numbering, leading manufacturers offer extensive customization. This includes laser-engraved or printed company logos, barcodes, QR codes, and custom text. These custom security seals enhance brand visibility and can be integrated into automated scanning systems for improved efficiency.

Parameter introduction

Material | PP PE Plastic | ||

Lock body size | 33.4*22.6mm | ||

Diameter | 2.5mm | ||

Fabrication process | Disposable injection molding process | ||

Lenght | 400mm | ||

Printing type | Laser printing or hot stamping | ||

Application | All kinds of Containers, Trucks, Tanks, Doors, Courier services, Bags, etc. | ||

Net weight | 19KG | ||

Packing | 100pcs/bag,50bag/big bag, 5000pcs/carton | ||

Moq | 1000 PCS | ||

The Sealing Process: Simple, Secure, and Effective

The application of a numbered plastic security seal is a straightforward yet critical procedure designed for maximum reliability.

Threading: The flexible pin or strap of the seal is threaded through the locking mechanism of the item to be secured. This could be the hasp of a door, the pull-tabs of a zipper on a bag, the latch of a meter, or the closing mechanism of a container.

Locking: The user then firmly inserts the pin into the seal body until it clicks into place. The internal, one-way locking barb or ball mechanism engages, preventing the pin from being withdrawn.

Verification and Recording: Once locked, the unique serial number on the seal is recorded in a manifest, database, or shipping document. The person responsible for opening the secure item at the destination will verify that this number matches the one on record and inspect the seal for any signs of tampering before breaking it.

This simple three-step process creates a powerful chain of custody that is easy to implement but difficult to defeat.

Manufacturing Excellence and Quality Assurance

The production of reliable numbered plastic security seals involves a precise manufacturing process to ensure consistency and strength. It begins with the selection of high-grade plastic resins, which are then injection-molded into the desired shape under high pressure and temperature. This creates a consistent and robust product. The numbering and marking phase is crucial; high-resolution laser engraving is preferred for its permanence, as it etches the information into the plastic surface, making it resistant to abrasion and fading. Finally, each batch undergoes rigorous quality control checks, which often include pull-strength tests to verify the locking mechanism meets specified security standards before being packaged for distribution.

Frequently Asked Questions (FAQ) for B2B Buyers

1. What is the typical tensile strength of a standard numbered plastic security seal, and is it sufficient for my application?

Tensile strength varies by model, but standard numbered plastic security seals typically range from 15 to 50 pounds of force (lbsf). For securing internal packages or lightweight items, a lower strength may suffice. For external cargo containers or high-value assets, we recommend high-security plastic seals with a tensile strength of 50 lbsf or more. It's crucial to match the seal's strength to the assessed risk level of your application.

2. Can we integrate the unique serial numbers from these seals into our existing inventory or tracking software?

Absolutely. The unique sequential numbering is a key feature for integration. Many B2B buyers use the serial numbers for automated data capture. You can request seals with barcodes or QR codes containing the number, which can be easily scanned and uploaded directly into your Track and Trace or Warehouse Management System (WMS), streamlining your audit and reconciliation processes.

3. How does a plastic seal compare to a metal seal in terms of security?

Plastic security seals offer an excellent balance of security, cost-effectiveness, and customization. They are highly effective against covert tampering and provide clear visual evidence of a breach. Metal seals, generally made of cable or bolt designs, offer higher tensile strength and are better at withstanding forceful attacks. The choice depends on your threat model: plastic is ideal for a wide range of general security needs, while metal is reserved for high-risk, high-value shipments where maximum physical resistance is required.

4. Are environmentally friendly or recyclable options available for plastic security seals?

Yes, growing demand for sustainable solutions has led manufacturers to develop eco-friendly alternatives. You can now source numbered plastic security seals made from recycled materials or bio-based plastics. It is important to discuss your sustainability requirements with your supplier early in the procurement process to identify the best available option that does not compromise on security integrity.