Plastic Seal Tag

1、The seal is made of PP plastic in one injection moulding, the seal is sandwiched with metal portions inner and does no longer alternate form at minus forty five ranges and above minus 50 degrees.

2、The seal is stamped or laser printed with agency logo, range and barcode.

3、Adjust the tightness of the seal at will, the pulling pressure can attain F≥50KG.

4、The shade can be made into red, blue, green, yellow, or different shades in accordance to consumer requirements.

5、High tensile strength to prevent damage and reduce dislodgement.

Advanced Features of Modern Plastic Seal Tags

Integrated Tracking Technology

Barcode Integration: Select models feature integrated barcodes that enable rapid scanning and automated serial number recording

Sequential Numbering: All seals include unique identification numbers for precise tracking and accountability

Custom Imprinting Options: Enhanced security through customized logos, text, or special markings that deter counterfeiting

Digital Compatibility: Designed to integrate seamlessly with existing inventory management and security systems

Engineered for Practical Application

Varied Break Strengths: Available in multiple strength ratings from lightweight (under 50 lbs) to heavy-duty options for different security requirements

Tear-Off Tab Design: Select models include convenient removal tabs that simplify disposal while ensuring seal destruction

Hasp Opening Compatibility: Designed with attention to aperture sizes to ensure compatibility with various hasp configurations

Tool-Free Removal: Lower strength seals can be removed manually or with basic tools, reducing operational complexity

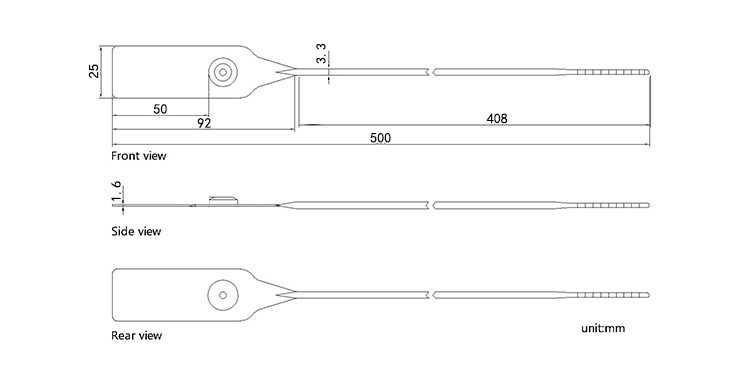

Specification

*Model | L018 |

*Material Type | PP/PE |

*Color | Green,Red,Yellow,Blue,White,Black etc. |

*Application | Tucks, meter boxes, post packages and bank money bags etc. |

Laser etch or hot stamping Customer's company name & Logo,Bar code etc. | |

*Plastic Seal Package | 100pcs per bag, 2000-5000 pcs/carton |

Strategic Advantages for Business Operations

Enhanced Operational Efficiency

The implementation of barcode plastic seals transforms security from an operational burden into a productivity enhancer:

Automated Data Collection: Barcode scanning eliminates manual recording errors and reduces processing time

Routine Inspection Efficiency: Quick visual verification and scanning capabilities accelerate security checks

Inventory Management Integration: Compatible with existing warehouse management systems for seamless operations

Time Optimization: Reduced administrative workload allows staff to focus on core business activities

Scalable Security Solutions

Flexible Security Levels: Right-strength solutions prevent over-securing or under-securing applications

Adaptable to Various Environments: Suitable for indoor and outdoor use across multiple industries

Customizable Security Protocols: Ability to match seal specifications to specific security requirements

Growth-Oriented Design: Scalable solutions that grow with your business needs

Comprehensive Application Scenarios

Logistics and Transportation Security

Shipping Container Security: Providing tamper-evidence for intermodal containers and truck shipments

Warehouse Management: Securing storage areas, high-value product cages, and sensitive materials

Last-Mile Delivery: Ensuring integrity of final delivery products to end customers

Cross-Border Shipments: Meeting international shipping security requirements

Commercial and Industrial Applications

Retail Security: Protecting high-value merchandise during storage and transportation

Manufacturing Quality Control: Sealing calibrated equipment and quality test samples

Aviation and Aerospace: Securing aircraft components, maintenance areas, and sensitive equipment

Utility and Energy Sector: Protecting meters, control panels, and access points

Measurable Business Benefits

Tangible Operational Improvements

Implementing plastic security tags delivers quantifiable benefits across multiple business areas:

Error Reduction: Automated barcode scanning decreases manual recording mistakes by up to 85%

Time Efficiency: Rapid application and verification processes reduce security-related labor costs

Theft Deterrence: Visible security measures discourage tampering and unauthorized access

Audit Compliance: Comprehensive tracking capabilities simplify compliance and reporting

Cost Optimization and Risk Management

Accident Prevention: Appropriate break strength selection reduces workplace injuries

Inventory Accuracy: Enhanced tracking improves inventory management precision

Loss Prevention: Effective security measures directly reduce shrinkage and theft losses

Insurance Compliance: Meets security requirements for optimal insurance coverage

Technical Specifications and Selection Guidance

Product Configuration Options

Break Strength Variants: Available from light-duty (under 50 lbs) to heavy-duty configurations

Barcode Technology: Compatible with standard and custom barcode symbologies

Material Composition: Durable plastic formulations for various environmental conditions

Size Specifications: Multiple hasp opening sizes to accommodate different application needs

Performance Characteristics

Environmental Resistance: Weather-resistant options available for outdoor applications

Temperature Tolerance: Stable performance across typical operational temperature ranges

Chemical Resistance: Withstands exposure to common industrial chemicals and cleaners

UV Protection: Options available with UV inhibitors for extended outdoor use

Frequently Asked Questions (FAQ)

Q1: How do barcode-equipped seals improve operational efficiency?

A: Barcode plastic seals significantly enhance efficiency by enabling rapid, automated scanning that eliminates manual serial number recording. This integration reduces processing time, minimizes human error, and provides immediate data integration with existing inventory management systems. The automation capability is particularly valuable for large-scale operations where time savings accumulate substantially.

Q2: What factors should we consider when selecting break strength?

A: Choosing the appropriate break strength plastic seals depends on your specific security needs versus accessibility requirements. Lower strength seals (under 50 lbs) offer convenience for frequent access points, while higher strength options provide enhanced security for high-value assets. Consider the balance between security level needed and the practicality of removal in daily operations.

Q3: Can these seals be customized with our company information?

A: Absolutely. Custom imprinted plastic seals are available with your company logo, specific color schemes, unique numbering sequences, and specialized barcodes. This customization not only enhances brand visibility but also provides an additional security layer against seal duplication or counterfeiting.

Q4: How do we ensure proper hasp compatibility?

A: Successful implementation requires verifying the 'minimum hasp opening' specification for your selected seal against your actual application requirements. We provide detailed dimensional specifications and application guidance to ensure proper fit. Our technical support team can assist with compatibility assessment for unusual or custom applications.