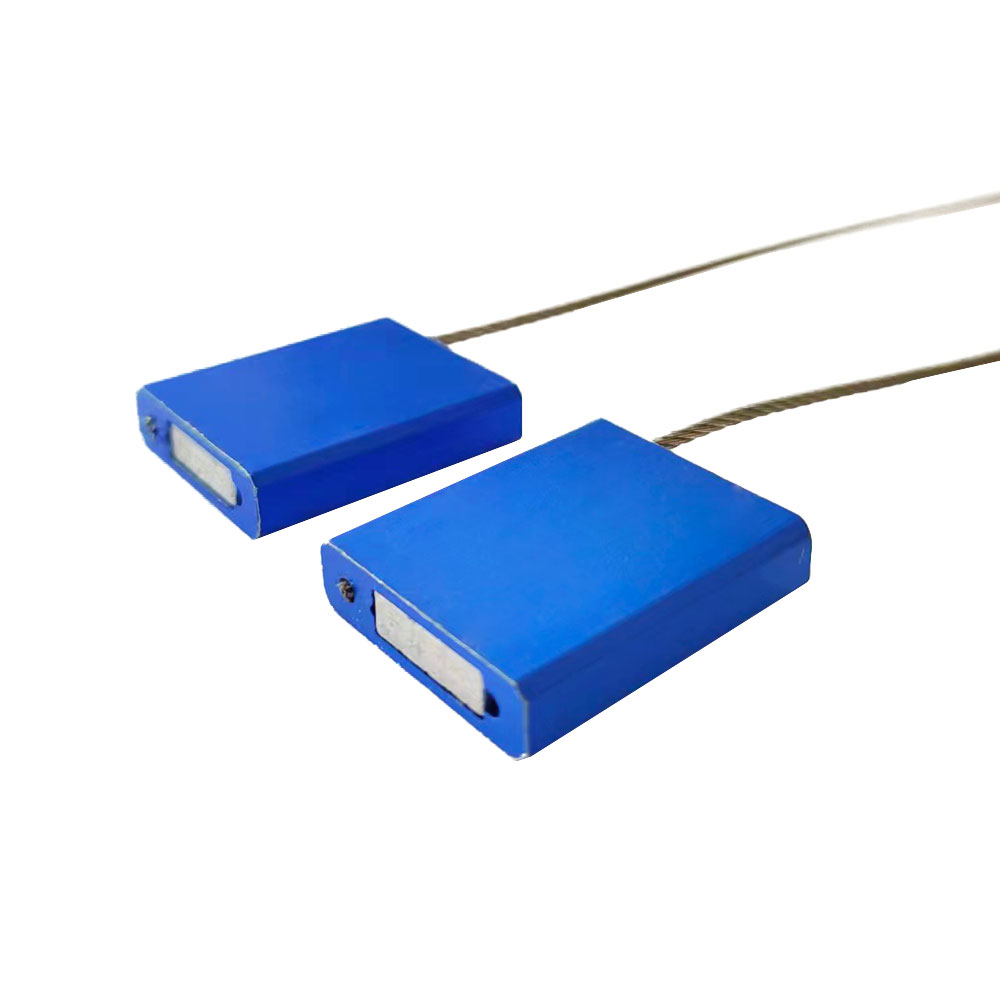

Aluminium Alloy Seal

Most of our cable seals are developed of galvanized metallic airplane cable, which will unravel upon cutting. This attribute minimizes unauthorized reuse of the seal.

Our cable seals consist of these delivered factors and benefits:

1.Improved locking mechanism to combat tampering.

2.Bar codes that in structure the distinctive serial quantity

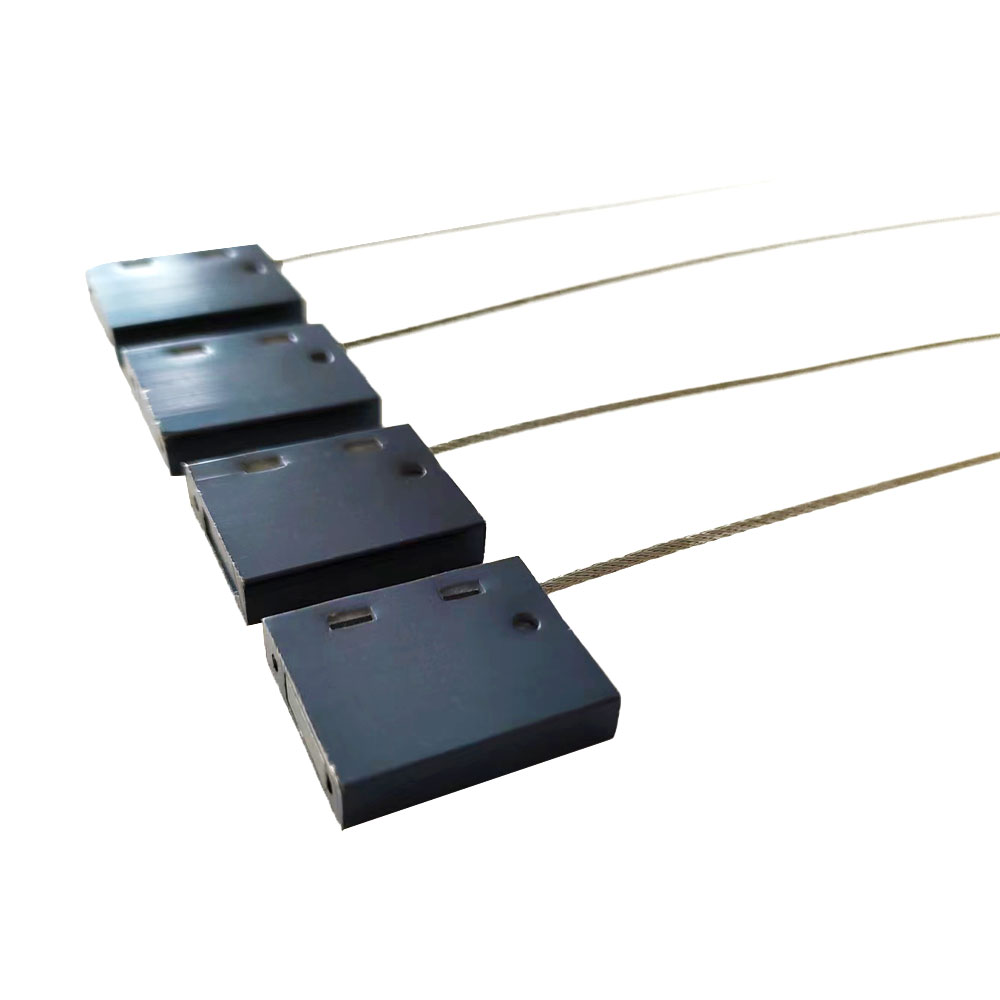

3.Lightweight (but durable) constructing to minimize transport costs.

4.Cable seals are moreover configured as adjustable measurement or regular length.

All of our cable seals are manufactured in offerings which are CTPAT compliant.

Cable seals are lengthy lasting and supposed for larger protection applications. They are reachable in special cable diameters and lengths for use in greater than a few applications.

Our 3.5mm and 5.0mm cable seals are compliant with ISO 17712:2013 and are rated as a immoderate safety seals.

Product Overview: Adjustable Sealing Solution Designed for Stringent Security Needs

The adjustable high-security aluminum alloy seal represents a key advancement in modern physical security technology, integrating industrial-grade materials, intelligent design, and intuitive operation. This product is designed for applications requiring disposable, non-reusable seals that can adapt to varying locking point sizes. Unlike fixed-length seals, its adjustable design offers unparalleled flexibility, while the combination of a high-strength aluminum alloy lock body and tamper-proof cable ensures superior durability and visible security. This product aims to provide B2B logistics management, asset protection, and compliance professionals with an ultimate tamper-proof sealing solution that combines reliability, adaptability, and clear legal evidentiary value.

Key Product Features Explained

1. Flexible Adjustable Length and Robust Locking Mechanism

The primary advantage of this product lies in its exceptional adaptability, solving the inventory and management challenges caused by varying locking point sizes.

Intelligent Adjustable Design: Users can freely thread the cable through the object to be sealed (such as bolts, valves, container locking bars) to customize the seal circumference as needed. This design ensures a tight, secure seal regardless of the size of the locking point, eliminating any unnecessary movement.

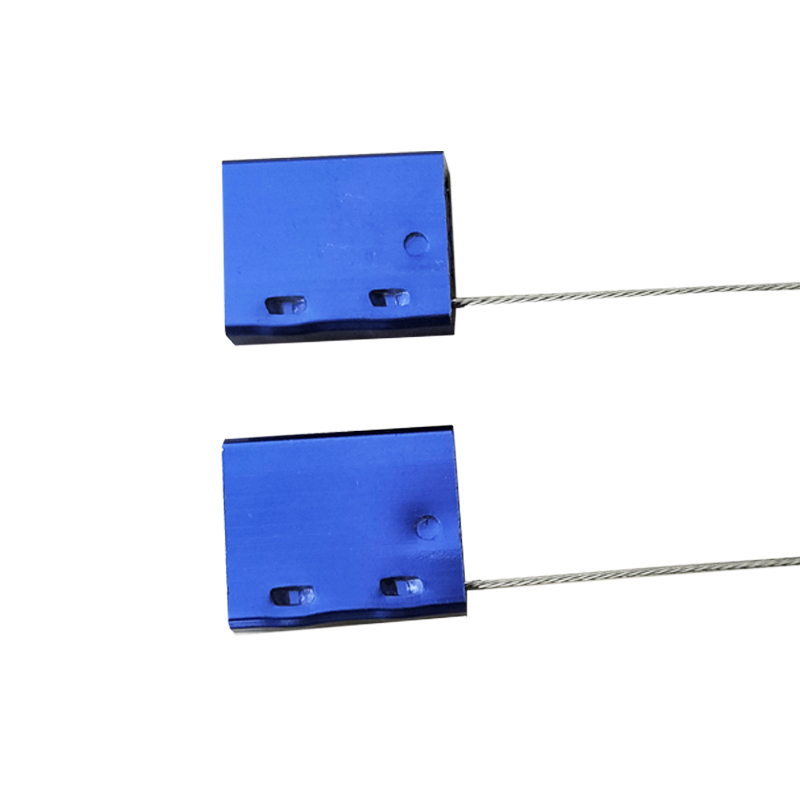

Simple Three-Step Locking Process: The operation follows an intuitive "insert-tighten-lock" process. First, insert the end of the steel cable into the locking channel of the aluminum alloy lock body; then, tighten the cable to eliminate slack; finally, by pulling the lock body or pulling the cable in the opposite direction, the internal one-time ratchet locking mechanism is triggered, achieving permanent locking. The entire process requires no additional tools to complete a high-security seal.

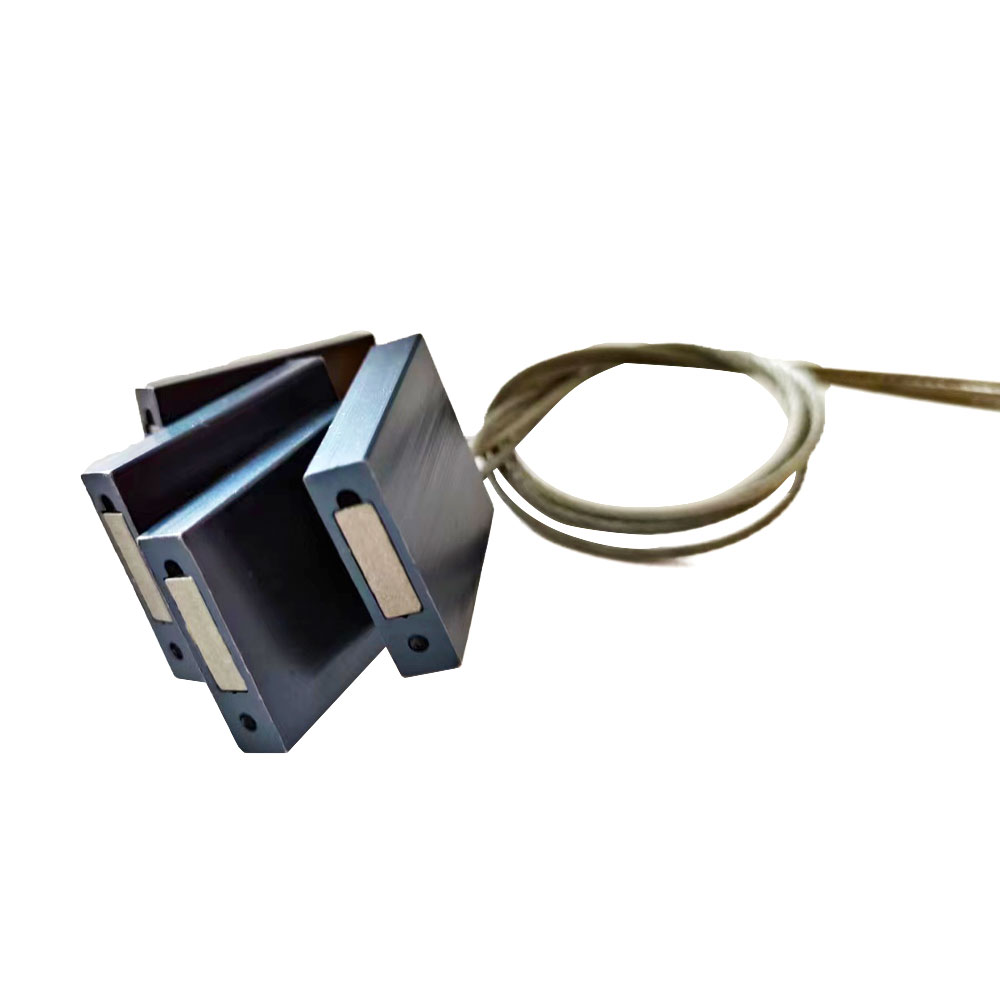

2. Ultimate Anti-Tampering and Anti-Reuse Features: Security is the cornerstone of this product; its design physically eliminates the possibility of covert tampering and reuse.

Forced Tool Destruction: Once the locking mechanism is fully triggered, the seal cannot be removed non-destructively. The only way to remove it is by physically cutting it with specialized cable cutters or bolt cutters, an act that itself constitutes indisputable evidence of destruction.

Active Anti-Reuse Design: To achieve the highest level of security, excess cable can be cut short immediately after installation, close to the lock body. The key design feature is that the cut cable end immediately unwinds. This characteristic prevents anyone from reinserting the cut cable into the lock body for spoofing or reuse, fundamentally eliminating "cut-and-reconnect" fraud and ensuring its absolute reliability as a single-use product.

3. High-Strength Materials and Durability: The product uses high-quality materials to withstand various harsh industrial and transportation environments.

Lightweight yet robust aluminum alloy lock body: The lock body is precision die-cast from aerospace-grade aluminum alloy, combining lightweight and high strength. It possesses excellent corrosion and impact resistance, and the surface can be anodized for enhanced wear resistance and offers a variety of color coding options.

High-Tensile Galvanized Steel Cable: The accompanying cable uses multi-strand galvanized steel wire, providing extremely high tensile strength (typically exceeding 1600N), effectively resisting violent pulling. The zinc coating provides excellent rust protection, ensuring long-term stable performance in harsh environments such as humidity and salt spray.

Key Applications

The flexibility and high security of adjustable aluminum alloy seals make them the preferred choice for several key industries:

International Logistics and Multimodal Transport: As the preferred seal for high-value cargo containers, especially suitable for special containers with varying locking bar sizes or requiring sealing at multiple points. Its adjustability ensures perfect fit, while its tamper-proof design meets stringent customs and insurance requirements.

Energy, Chemicals, and Utilities: Used to seal tanker inlets, chemical drum valves, electricity metering boxes, and gas pressure regulating devices. Adjustable length allows it to easily accommodate various sizes of valve handwheels, flanges, or instrument panels, providing reliable tamper-proof protection for assets.

Manufacturing and Warehouse Security: Seals raw material warehouses, finished product containers, high-value equipment, and calibration instruments. Its flexibility facilitates unified inventory management and reduces the need for multiple seals due to different locking point specifications.

Retail and Cash Logistics: Suitable for ATM cash drawers, cash bags, high-value merchandise display cases, etc. Its shear-and-open feature provides additional security for cash transport.

Government, Military, and Evidence Preservation: In situations requiring the highest level of physical evidence chain integrity, such as document bags, evidence boxes, and armories, this seal provides visually clear and legally admissible proof of integrity.

Applications

specification:

Material | Aluminum alloy lock + galvanized steel wire |

Colour | Red,green,white,yellow,blue and etc |

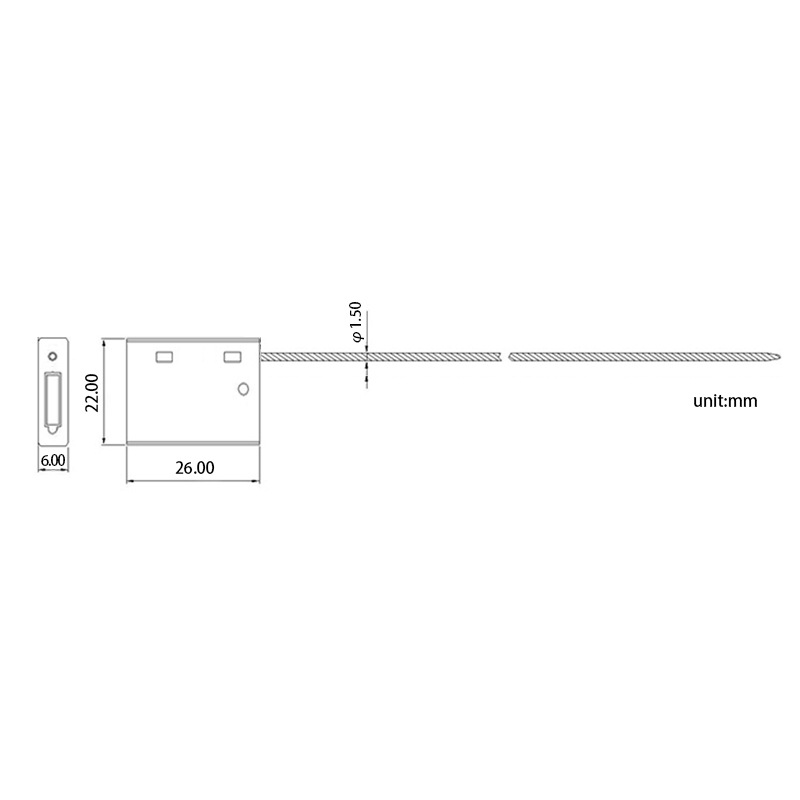

Lock size | 26x22x6mm |

Diameter | 1.5mm,2mm,.25mm |

Length | 240mm or any length as required |

Printing | Hot stamping or laser printing of logos, bar codes and codes |

Certificate | ISO4500:2018,ISO14001:2015,ISO9001:2015,SGS |

Application | This product is suitable for container shipping, tanker transportation, truck freight, trailer freight and so on |

Frequently Asked Questions (FAQ)

1. Does the "cable unwinding after cutting" design affect the seal's strength before cutting? How is it ensured that it cannot be opened by trickery after locking?

No. The unwinding characteristic only occurs at the cut end, determined by the cable's twisted structure, and does not affect the seal's overall tensile strength. After locking, the one-way ratchet or clamping device inside the lock body firmly grips the cable; any attempt to pull the cable out in the opposite direction will only tighten the grip. There is no way to open the lock body by trickery without destructive cutting; this is the core principle of its high-security mechanical seal.

2. Do you offer options for different diameters or materials of cable? What are the specific aluminum alloy models for the lock body?

Yes, we offer a variety of configurations to meet different security levels and budget requirements. Customers can choose galvanized steel or stainless steel cables of different diameters (e.g., 2.0mm, 2.5mm, 3.0mm). The lock body is typically made of 6061 or 7075 series aluminum alloy, both renowned in industrial applications for their excellent strength-to-weight ratio and corrosion resistance. Our sales engineers can recommend the most suitable material combination based on your specific application environment (e.g., marine transport, chemical plant).

3. Can we personalize the lock body? How does this help with supply chain tracking?

Absolutely. We offer professional customization services, laser engraving or embossing the following information onto the aluminum alloy lock body surface: unique serial number, company logo, QR code/barcode, and date code. These markings are permanent and indelible. By scanning the QR code, the physical seal can be linked to shipping documents and cargo information in your supply chain management platform, enabling end-to-end digital tracking and auditing from sealing and in-transit monitoring to receipt and verification, greatly improving transparency and management efficiency.

4. Does this seal comply with international security standards (e.g., ISO 17712)? Our range of adjustable high-security aluminum alloy seals includes specially designed models that meet or exceed the mechanical performance requirements for "high-security seals" in the ISO 17712 standard, including tensile, shear, and impact resistance tests. If your business involves international shipping regulated by this standard, please specify the model requiring ISO 17712 certification when purchasing; we will provide the corresponding test reports and documentation. As a responsible security seal manufacturer, we are committed to helping our customers meet global trade compliance requirements.