waterproof cable seal

Product Advantage

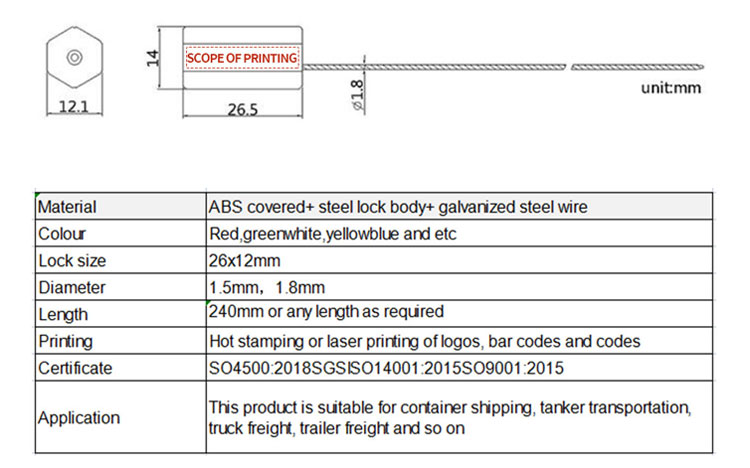

This product consists of spring type steel structure lock body, head coated with plastic, wire diameter of 1.8mm.

1. Wear-resistant and anticorrosive, not easy to damage

2.Good water resistance and tightness

3.Printing method (laser printing and hot stamping), LOGO, serial number, number, two-dimensional code, etc

4.The length and diameter of the wire can be adjusted, which can be customized according to customer requirements

All of our cable seals are manufactured in offerings which are CTPAT compliant.

Our 3.5mm and 5.0mm cable seals are compliant with ISO 17712:2013 and are rated as a immoderate safety seals.

Waterproof Cable Seals: Superior Protection for Demanding Environments

In global logistics and transportation, ensuring cargo integrity against both tampering and environmental challenges is paramount. Waterproof cable seals represent a critical advancement in security technology, combining robust physical protection with exceptional resistance to moisture, dust, and extreme weather conditions. These specialized seals are engineered with a unique locking mechanism and durable materials to provide reliable, tamper-evident security for high-value or sensitive shipments across supply chains.

Designed to perform where standard seals fail, waterproof security seals offer businesses a proven solution to prevent unauthorized access while withstanding the harsh conditions of international transit. From maritime shipping to cross-continental trucking, these seals ensure that security remains intact from origin to destination.

Key Features & Technical Advantages

Advanced Weatherproof Construction

The waterproof cable seal is engineered with precision to deliver uncompromising performance:

Fully Sealed Lock Body: The lock mechanism is encapsulated within a high-density plastic or coated metal housing, preventing water, dust, and other contaminants from entering the internal components. This ensures reliable operation in rain, snow, and high-humidity environments.

Corrosion-Resistant Materials: The high-tensile steel cable and lock components are often treated with zinc, nickel, or polymer coatings to resist rust and corrosion, significantly extending the seal's service life even in saline or chemically aggressive atmospheres.

Temperature Resilience: Manufactured from materials that remain flexible and functional across a wide temperature range, these seals maintain their integrity from freezing arctic conditions to intense desert heat.

Tamper-Evident Locking Mechanism

Security is ensured through a sophisticated and reliable internal system:

Internal Spring-Ball Design: When the lock head is inserted into the lock body, internal steel balls are forced into corresponding grooves under spring pressure. This creates a secure, irreversible lock that cannot be disengaged without causing visible, irreversible damage.

High-Strength Steel Cable: The flexible yet extremely strong cable is difficult to cut with standard tools, providing a formidable physical barrier against tampering. The cable's flexibility allows it to secure a wide variety of hasps, doors, and valve handles.

Destructive Removal: As a single-use device, the seal must be cut to be removed, providing absolute evidence of any access attempt. This tamper-evident security feature is crucial for chain-of-custody documentation and incident investigation.

Versatile Applications in Global Supply Chains

The waterproof design of these cable seals makes them indispensable across numerous industries and scenarios:

International Container Shipping: Protecting sea freight containers from moisture and tampering during long ocean voyages.

Bulk Liquid Transport: Securing the hatches and valves of oil tankers, chemical carriers, and food-grade liquid transports.

Overland Trucking and Rail: Ensuring the security of truck doors and railcar fittings through diverse weather conditions.

Outdoor Storage and Energy: Ideal for sealing equipment in construction, mining, and energy sectors where exposure to the elements is unavoidable.

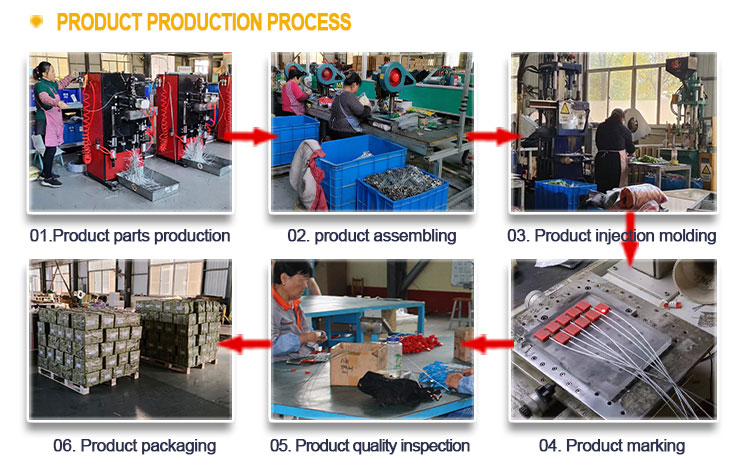

Product Production Process

Raw materials - Wire production - Lead seal wire assembly - Product injection - Product marking - Quality inspection

Frequently Asked Questions (FAQ)

Q1: How does the waterproof feature actually work, and what level of exposure can it withstand?

A: The waterproof capability is achieved through a combination of a tightly toleranced lock housing and sealing gaskets or injected sealants that prevent moisture ingress. Our waterproof cable seals are typically rated to withstand prolonged exposure to heavy rain, spray, and temporary immersion, making them highly suitable for maritime applications and overland transport through severe weather. Specific IP (Ingress Protection) ratings can be provided upon request.

Q2: Are these cable seals compliant with international security standards like ISO 17712?

A: Yes, our high-security waterproof cable seals are designed and tested to meet the tamper-evidence and strength requirements of ISO 17712 for "High-Security Seals." This ensures they are accepted by customs authorities and major logistics providers worldwide, facilitating smooth cross-border transactions.

Q3: What is the tensile strength of the cable, and what tools are required for removal?

A: The steel cable seals offer a high tensile strength, typically ranging from 1,000 to over 2,500 pounds, depending on the model. Removal is intentionally difficult and requires heavy-duty cable cutters or bolt cutters. This design ensures that the seals provide a genuine physical barrier and cannot be compromised with simple tools.

Q4: Can these seals be customized with company identification?

A: Absolutely. We offer comprehensive customization options, including permanent laser engraving of unique sequential numbers, company logos, and barcodes. This enhances accountability, deters counterfeiting, and seamlessly integrates the seals into your existing tracking and inventory management systems.