Plastic coated double lock wire seal

Steel Wire Lead Seal with Double-locking Arrangement

The steel wire lead seal is a locking material made of steel lock body with an ABS plastic and Galvanized stell wire.

Which is composed of a signing and sealing device for the information management of business links such as meter inspection, meter installation and connection, meter reading, electricity consumption inspection and electricity consumption audit, and the integration of power marketing field work into the overall information management.

Product Overview & Key Features

The Steel Wire Lead Seal with Double-locking Arrangement is meticulously designed for maximum reliability. Its construction utilizes a high-tensile, galvanized steel wire that resists cutting and sawing attempts. The lock body, crafted from reinforced ABS plastic, houses a sophisticated double-locking mechanism that securely grips the wire cable once inserted. This dual-stage locking system ensures that any attempt to force the seal open results in irreversible damage, providing clear and immediate tamper evidence.

Unmatched Customization for Brand & Function

A significant advantage of this double-locking security seal is its high degree of customization. B2B buyers can specify:

Cable Lengths: Tailored to specific application needs, from securing small utility meters to large cargo container doors.

Color Coding: Assign different colors to departments, security levels, or routes for instant visual identification and inventory management.

Custom Markings: Utilizing high-precision laser printing, these seals can be permanently marked with company logos, sequential barcodes, QR codes, unique text, or bespoke number ranges. This facilitates seamless tracking, authentication, and integration into digital asset management systems.

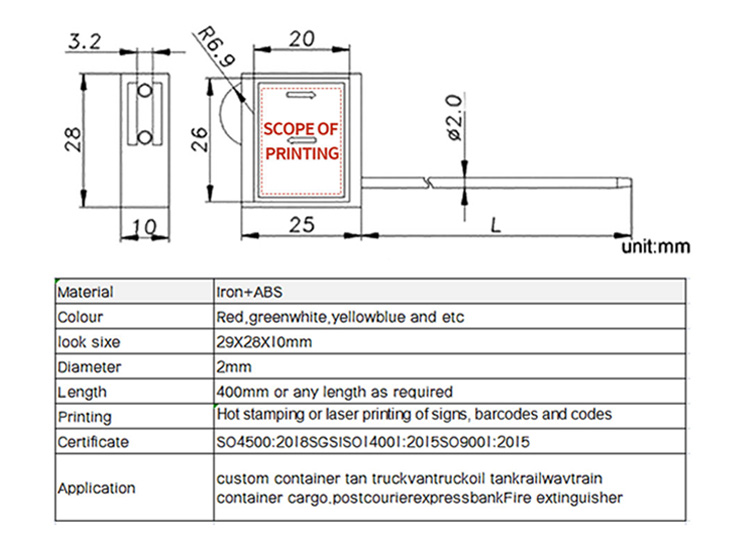

Technical Specifications & Material Superiority

The exceptional performance of this lead seal is a direct result of its premium material composition and precision engineering.

Material Composition: The seal is a composite of three key materials:

Galvanized Steel Wire: Provides the core tensile strength and resistance to corrosion and physical attack.

Steel Lock Body: Forms the internal, high-security core of the locking mechanism.

ABS Cover: Encases the lock body, offering protection against environmental factors, impact, and providing a smooth surface for high-quality laser printing.

Marking Type: Laser printing ensures that all markings—whether logos, barcodes, or serial numbers—are permanent, smudge-proof, and resistant to fading, even in harsh weather conditions.

![]()

Extensive Application Range

The versatility and robustness of the Steel Wire Lead Seal make it the preferred choice across a wide spectrum of industries.

Logistics & Transportation Security

This seal is indispensable for securing:

Cargo containers and truck trailer doors during transit, ensuring the integrity of goods from origin to destination.

Tanker trucks and rail car doors, protecting high-value or hazardous materials.

Airline trolleys, safeguarding in-flight supplies and cargo.

Energy & Industrial Asset Protection

Beyond logistics, these seals are critical for:

Utility meters and valves, preventing unauthorized access and tampering that could lead to revenue loss or safety hazards.

Valves in the petrochemical industry, where ensuring the position and security of critical infrastructure is non-negotiable for operational safety and compliance.

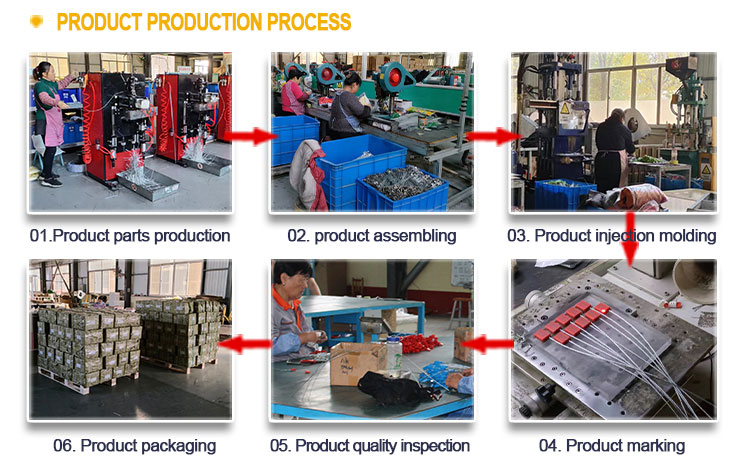

The Manufacturing Process: A Commitment to Quality

The production of these high-security seals follows a rigorous, multi-stage process to guarantee consistency and reliability:

Raw Material Sourcing: High-grade galvanized steel wire and ABS plastic pellets are sourced and subjected to quality checks.

Wire Production: The steel wire is cut and galvanized to specific lengths and tensile strengths.

Lead Seal Wire Assembly: The wire is fitted to the internal steel lock body components.

Product Injection: The assembly is placed into a mold, where the ABS plastic is injection-molded around it to form the final, robust seal body.

Product Marking: The finished seals are marked using laser printers according to customer specifications (logos, barcodes, etc.).

Quality Inspection: Each batch undergoes stringent testing for pull strength, lock function, and marking clarity before packaging and dispatch.

Frequently Asked Questions (FAQ) for B2B Buyers

1. What is the primary advantage of the double-locking mechanism in a steel wire lead seal?

The double-locking mechanism provides two distinct stages of engagement within the lock body. This makes it significantly more difficult to disengage without causing visible damage compared to a single-lock design. It offers a higher level of security and more definitive tamper evidence, which is crucial for high-value shipments and sensitive assets.

2. How does the tensile strength of this seal compare to a standard plastic seal?

The integration of a galvanized steel wire core gives this seal a much higher tensile strength, typically several times greater than that of a standard plastic seal. This makes it resistant to pulling, stretching, and breaking under force, offering superior protection against physical attack.

3. Are the custom laser markings durable enough for outdoor or industrial use?

Yes. Laser printing permanently etches the markings into the ABS surface of the seal. This method creates markings that are highly resistant to abrasion, chemicals, and UV exposure, ensuring that logos, barcodes, and serial numbers remain legible throughout the seal's lifecycle, even in harsh outdoor or industrial environments.