Steel wire seals

Product advantages

Wide range of applications, easy to apply and seal, easy to operate without the help of tools

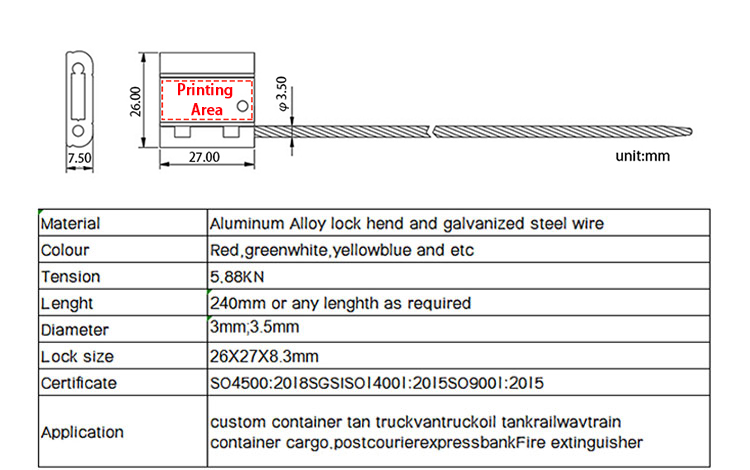

Hot stamping or laser printing of logo, barcode and code

High tensile strength, not to be damaged and cut off

Effective temperature range -40℃ to 110℃

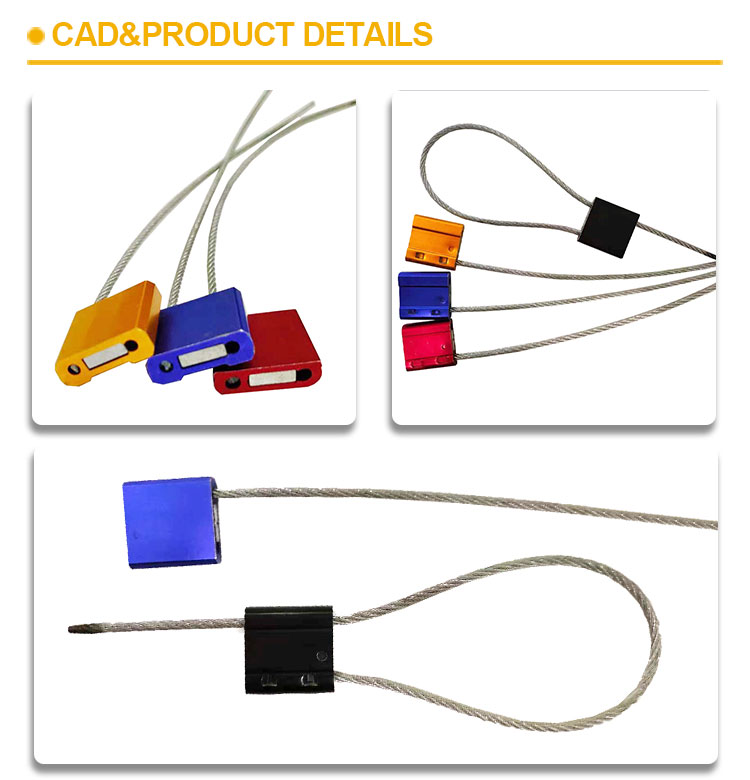

Color: red, orange, yellow, green, blue, white, gray, black, etc. or according to customer requirements

Model

Structure: There is a combination of steel wire and lock body, Aluminum alloy + galvanized steel wire

Use: The product is suitable for all kinds of containers, container trucks, electric meters, water meters, scientific instruments, ordnance, container short-distance transport, trucks, trailers freight, fire equipment seal, confidential seal railroad and other fields

Shipping: 100pcs/pack, 10 packs/box

Service: can be customized length, color

Logo, serial number, barcode and logo can be printed according to user requirements.

As a premier manufacturer and supplier in the security sealing sector, we present our comprehensive line of High-Strength Steel Wire Seals. These products represent the benchmark for tamper-evident security in environments where asset protection, safety, and chain-of-custody integrity are non-negotiable. Engineered with a core of galvanized or stainless steel wire and a robust locking mechanism, these seals are designed to deliver unparalleled physical resistance to manipulation, cutting, and unauthorized access. Their fundamental design principle—combining flexible, high-tensile cable with a permanent, one-time lock—makes them an exceptionally versatile and reliable solution. For international B2B buyers, our steel wire security seals are not merely products; they are critical components of risk management protocols, ensuring the safe and accountable transit of goods, the security of fixed assets, and compliance with stringent industry regulations across a remarkably broad spectrum of applications.

Core Product Characteristics & Engineering Excellence

The widespread adoption of steel wire seals across critical industries is a direct result of their superior and adaptable design, which offers a unique combination of flexibility, strength, and evident security.

1. Robust Construction for Unmatched Durability

The integrity of the seal begins with its material science and mechanical design.

High-Tensile Steel Wire Core: The seal utilizes a multi-strand, galvanized steel wire or stainless steel cable as its primary component. This provides exceptional cut resistance and tensile strength, capable of withstanding significant force, vibration, and environmental stress without failure. The galvanization process offers superior corrosion resistance, which is crucial for maritime, chemical, and outdoor applications.

Permanent, Irreversible Locking Body: The wire is secured within a locking body typically constructed from hardened metal (such as aluminum or steel alloy) or high-impact engineering plastic with a metal core. The internal mechanism—often a ball-lock, crimp, or exclusive patent design—engages the wire permanently. Once locked, the mechanism cannot be disengaged without causing destructive, visible damage to the entire seal assembly.

Tamper-Evident by Design: Any attempt to compromise the seal—whether by cutting the wire, prying the lock, or attempting to extract the cable—results in clear, irreversible physical damage. This provides definitive proof of tampering for audits, inspections, and legal verification.

2. Unparalleled Versatility and Adaptability

The defining advantage of a steel wire seal is its ability to secure a vast array of assets with varying geometries.

Flexible Application: Unlike rigid bolt seals, the pliable steel cable can be threaded through irregularly spaced locking holes, around handles, through hasp assemblies, and across complex sealing points. This makes it ideal for securing tankers, container doors, valves, and meter housings where fixed-length seals are impractical.

Customizable Configuration: Key specifications, including cable diameter , cable length, lock body material, and color, can be tailored to specific customer requirements. This ensures an optimal fit and security level for everything from a small electric meter to a large shipping container.

High-Visibility Marking & Traceability: The lock body surface is designed for permanent identification. We employ laser engraving or indented marking to apply unique sequential serial numbers, barcodes, QR codes, company logos, and inspection dates. This facilitates seamless integration into digital tracking systems, enabling electronic verification and creating a reliable audit trail for supply chain management.

Comprehensive Application Scenarios

The application scope of industrial steel wire seals is exceptionally wide, spanning virtually every sector that requires verifiable security for movable or fixed assets. They are the universal solution for preventing theft, leakage, and unauthorized access.

By Industry Sector:

Energy, Petroleum & Chemical: Essential for sealing tanker truck hatches, pipeline valves, wellheads, storage tank openings, and meter panels. They prevent product theft, diversion, and unauthorized tampering with sensitive equipment, ensuring safety and revenue protection in petroleum transportation and chemical processing.

Transportation, Logistics & Container Shipping: The global standard for sealing ISO shipping containers, trailer doors, and railcar hatches. They are critical for maintaining the integrity of goods in domestic and international transit, supporting compliance with programs like C-TPAT and ISO 17712 for container security.

Government, Customs & Defense: Used by customs authorities for sealing bonded warehouses and in-transit cargo, and by defense and aerospace sectors for securing sensitive equipment, armament cases, and evidence. They provide the high-security, tamper-evident features required for official and confidential use.

Utilities & Public Infrastructure: Widely applied to electric meters, water meters, and gas meters to deter tampering and ensure accurate billing. Also used on fire hydrants, fire equipment cabinets, and public utility access points.

Manufacturing, Mining & Heavy Industry: Used for sealing packaging drums, product inspection samples, raw material storage, and equipment panels in mining and processing facilities. They secure tools, scientific instruments, and control panels against unauthorized use.

By Specific Use Point:

Vehicles & Transport: Tanker trucks, box trailers, shed cars, freight wagons.

Fixed Assets & Infrastructure: Meter housings, valve boxes, confidential railway equipment, storage tank manways with smaller lock holes.

Portable Assets: Weapons cases, inspection equipment, high-value toolboxes, evidence bags.

In summary, wherever there is a need for a flexible, high-integrity, one-time lock that provides clear evidence of its status, the steel wire security seal is the proven and trusted solution.

Frequently Asked Questions (FAQ)

1. Can we order custom lengths and serial number sequences to match our existing asset management system?

Absolutely. As a direct manufacturer, we specialize in customization to fit your operational workflow. You can specify the exact cable length needed for your application, and we can provide consecutive or randomized serial numbering according to your alphanumeric scheme. This data can be laser-marked onto the seal and pre-loaded into a report for easy integration with your asset tracking or logistics software, ensuring full traceability from the moment of purchase.

2. Are these seals compliant with international security standards for shipping containers, such as ISO 17712?

Yes. Specific models within our steel wire seal range are independently tested and certified to meet the ISO 17712 standards for "High-Security Seals." This certification verifies their resistance to forced entry, covert entry, and environmental conditions. If your business involves international containerized shipping, it is crucial to specify and use ISO 17712-certified seals to meet the requirements of carriers, ports, and customs authorities globally. We provide full certification documentation for compliant product lines.

3. How do these seals perform in extreme environments, such as chemical exposure or saltwater conditions?

We offer material grades specifically engineered for harsh environments. For standard corrosion resistance, hot-dip galvanized steel wire is highly effective. For extreme chemical exposure or permanent outdoor/saltwater use (e.g., offshore platforms, chemical tankers), we recommend upgrading to 304 or 316 stainless steel cable and an anodized aluminum or stainless steel lock body. This combination provides maximum resistance to rust, corrosion, and UV degradation, ensuring the seal's longevity and performance integrity in the most demanding industrial and marine applications.