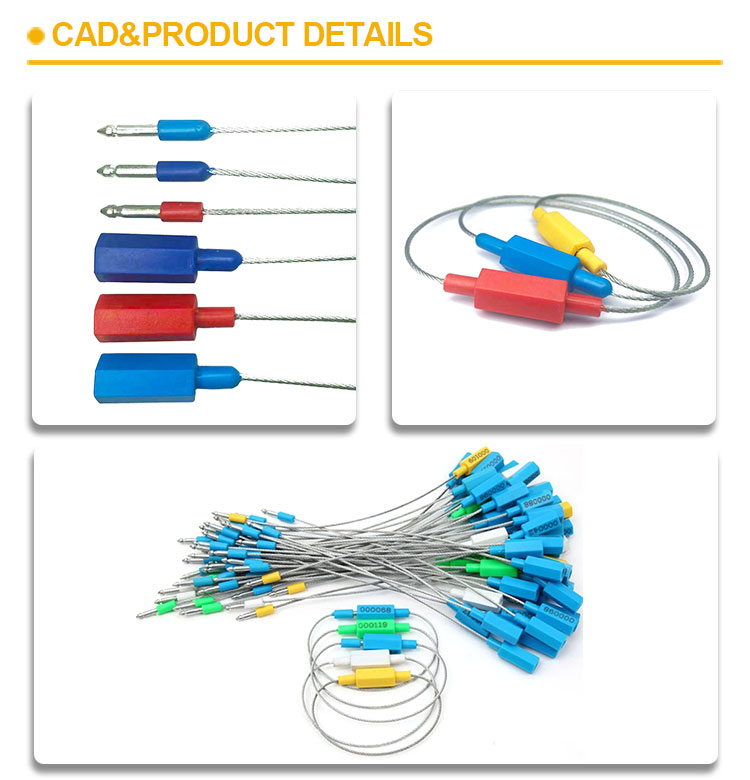

anti tamper wire seals

Most of our cable seals are developed of galvanized metallic airplane cable, which will unravel upon cutting. This attribute minimizes unauthorized reuse of the seal.

Our cable seals consist of these delivered factors and benefits:

1.Improved locking mechanism to combat tampering.

2.Bar codes that in structure the distinctive serial quantity

3.Lightweight (but durable) constructing to minimize transport costs.

4.Cable seals are moreover configured as adjustable measurement or regular length.

5.We provide custom service (color, material,LOGO, wire diameter and length)

All of our cable seals are manufactured in offerings which are CTPAT compliant.

In today's global supply chain environment where asset protection and tamper evidence are paramount, anti-tamper wire seals represent a sophisticated class of security devices that combine physical resilience with versatile application capabilities. These specialized seals feature a robust construction of galvanized steel wire encapsulated in a durable ABS outer layer, creating a security solution that effectively resists corrosion, weathering, and physical manipulation. For international B2B buyers across logistics, transportation, utilities, and manufacturing sectors, understanding the technical specifications and application benefits of these high-security wire seals is essential for implementing reliable tamper-protection systems that safeguard valuable assets throughout their operational lifecycle.

Technical Specifications and Structural Advantages

The exceptional performance of anti-tamper wire seals derives from their meticulously engineered material composition and design features that address common vulnerabilities in security sealing applications.

Superior Material Composition

The coe of these security devices consists of a galvanized steel wire with diameters of either 1.5mm or 1.8mm, providing substantial tensile strength that resists cutting, pulling, or sawing attempts. This steel core is further protected by an ABS outsourcing structure that adds significant durability while creating a barrier against environmental factors that typically compromise lesser security seals. The combination of these materials results in a wear-resistant anti-corrosion seal that maintains its integrity even when deployed in challenging outdoor or industrial environments where moisture, chemicals, or temperature fluctuations are present.

Customization Capabilities for Brand Integration

Beyond their security functions, these tamper-evident wire seals offer extensive customization options that enhance both practicality and brand security. The lock body accommodates various marking technologies including:

Sequential numbering for precise asset tracking and audit trail creation

Corporate logos that reinforce brand identity while deterring unauthorized seal replacement

Barcodes and QR codes that enable rapid digital scanning and integration with inventory management systems

This customization flexibility allows organizations to implement a coordinated security sealing system that aligns with their operational workflows and visual identity requirements.

Application Versatility Across Industries

The unique structural characteristics of anti-tamper wire seals make them suitable for diverse security applications across multiple sectors where reliable tamper evidence is required.

Transportation and Logistics Security

In logistics operations, these steel wire security seals provide dependable protection for:

Shipping containers and truck trailer doors during transit

Airline cargo and railcar door mechanisms

Warehouse security systems and storage facility access points

The adjustable cable length, typically starting at 240mm with extension capabilities, ensures compatibility with various locking mechanisms commonly found throughout the supply chain.

Utility and Industrial Applications

Beyond transportation, these anti-tamper devices serve critical functions in:

Utility meter security for electricity, water, and gas measurement equipment

Industrial equipment monitoring and maintenance access points

Retail security applications for high-value merchandise protection

The tightening-type mechanism allows for precise adjustment to different diameters, creating a secure fit that cannot be loosened without visible damage to the seal assembly.

Operational Mechanism and Installation Protocol

The functional efficiency of anti-tamper wire seals stems from their straightforward yet highly effective operational principle. The seal employs a tightening-type mechanism that permits arbitrary adjustment during installation, enabling security personnel to achieve an optimal fit for each specific application. Once positioned through the hasp or locking point, the seal is securely locked using simple hand pressure that engages the internal locking mechanism. This process requires no specialized tools, facilitating rapid deployment across multiple security points.

After locking, the seal cannot be removed without cutting the galvanized steel wire, which requires wire cutter tools and leaves unequivocal evidence of tampering. This deliberate design ensures that any attempted breach is immediately apparent during routine inspections, providing clear tamper evidence that triggers appropriate security responses. The irreversible nature of the locking mechanism establishes a reliable chain of custody for secured assets, making these seals particularly valuable for high-security applications where accountability is paramount.

Manufacturing Excellence and Quality Assurance

The production of reliable anti-tamper wire seals follows a rigorous manufacturing process that emphasizes consistency and performance. The galvanized steel wire undergoes specialized treatment to enhance its corrosion resistance and mechanical strength before being precision-cut to specified lengths. The ABS components are injection-molded under controlled conditions to ensure dimensional accuracy and material integrity. Each production batch undergoes stringent quality control assessments, including pull-strength testing and locking mechanism verification, to ensure consistent performance that meets the exacting requirements of B2B security applications.

Frequently Asked Questions (FAQ) for B2B Buyers

1. How does the ABS coating enhance the performance compared to bare steel seals?

The ABS outsourcing structure provides multiple advantages: it prevents corrosion in humid environments, reduces false tamper indications from incidental contact, creates a smooth surface for permanent marking, and insulates against temperature transfer. This coating significantly extends the service life of the galvanized steel wire core in challenging environmental conditions.

2. Are these seals compliant with international security standards such as ISO 17712?

Yes, high-quality anti-tamper wire seals from reputable manufacturers are designed to meet or exceed ISO 17712 standards for tamper-evident seals. Buyers should specifically request certification documentation to ensure compliance with their industry's regulatory requirements and security protocols.