Plastic Tamper Evident Seals

Plastic tamper-evident seals are security devices designed to indicate if a container, package, or item has been tampered with or opened.These seals are crucial for maintaining the integrity and security of products during storage and transit.

Material:Made of high quality flame retardant PP, PE plastic.

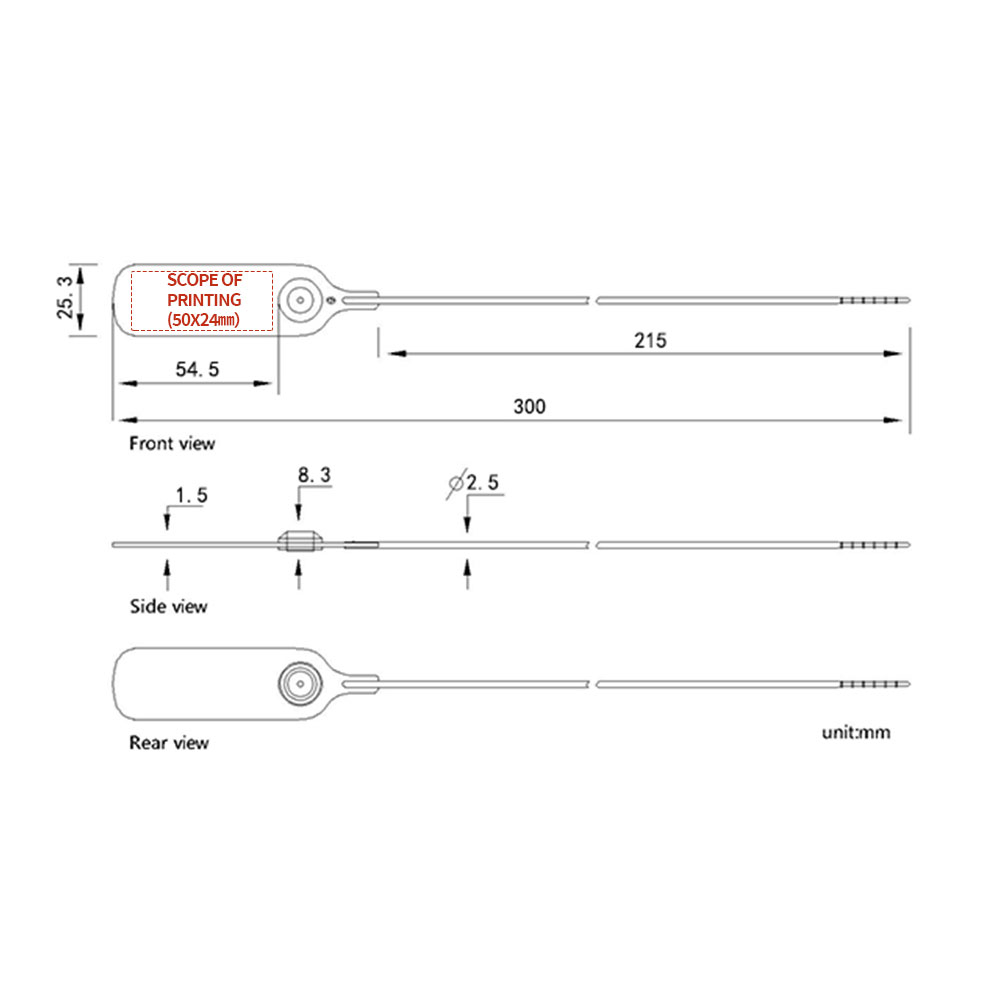

specification:300 mm

Feature:This product adopts one-time injection molding process, fixed sealing, safer to use.

Color:Red, blue, yellow, green, and other colors

Marked Price:50*24mm

Moq:1000pcs

OEM/ODM: Accept OEM and ODM order

Core Product Features & Design Philosophy

Our plastic tamper-evident seals are designed with a singular focus: to provide unambiguous evidence of interference through a combination of intelligent design, reliable materials, and versatile application features.

1. Definitive and Irreversible Tamper Indicators

The primary function of these seals is to communicate a breach of integrity instantly and clearly.

Visible, Destructive Failure: Our seals are engineered to fail conspicuously upon any attempt at removal or unauthorized opening. This failure manifests as a permanently broken seal body, a severed locking mechanism, or a fractured strap. The damage is designed to be impossible to repair or disguise, providing immediate visual confirmation of tampering.

Advanced Indicator Technologies: Beyond physical breakage, we offer seals with integrated tamper-indicating features such as specially formulated adhesives that leave a "VOID" pattern on the substrate, or color-change materials that activate upon manipulation. These multi-layered indicators provide an extra level of security assurance for high-risk applications.

2. Robust Construction for Enhanced Security

Security effectiveness hinges on the seal's ability to resist compromise and forgery.

Engineered Material Integrity: We utilize high-grade, engineered plastics such as polypropylene, polycarbonate, or ABS. These materials are selected for their strength, durability, and resistance to environmental stress, ensuring the seal remains intact under normal handling but fails definitively under tampering attempts.

Difficult to Replicate Designs: Our proprietary mold designs and manufacturing processes create unique structural elements that are extremely difficult to duplicate or counterfeit. This anti-fraud characteristic is crucial for protecting against the introduction of fraudulent goods into the supply chain and maintaining the seal's role as a trusted security device.

3. Extensive Variety and Functional Adaptability

Recognizing the diverse needs of global industries, we offer a broad portfolio to suit any application.

Diverse Form Factors: Our product line includes a wide variety of seals in numerous sizes, shapes, and locking mechanisms. This includes pull-tight seals, adhesive labels, barrel plugs, and wrap-around bands, each designed to suit specific packaging types and security needs, from small vials and bottle necks to large drum lids and shipping containers.

Seamless Application: Designed for efficiency, most seals can be applied quickly without the need for specialized tools, integrating smoothly into high-speed packaging and logistics operations without creating bottlenecks.

4. Comprehensive Customization for Traceability and Branding

Transforming a standard security device into a powerful tool for tracking and brand communication.

Full-Scale Custom Marking: We provide extensive customization options, including high-resolution printing, laser etching, or sequential numbering. This allows for the permanent application of unique identifiers such as serial numbers, QR codes, 2D data matrix codes, batch numbers, and company logos directly onto the seal.

Enhanced Supply Chain Visibility: This customization enables unparalleled traceability and audit control. Each seal becomes a unique data point that can be scanned and logged, providing a digital history of the product's journey and significantly enhancing supply chain security and accountability.

Parameter introduction

Material | PP PE Plastic | ||

Lock body size | 54*25mm | ||

Diameter | 2.5mm | ||

Fabrication process | Disposable injection molding process | ||

Lenght | 300mm | ||

Printing type | Laser printing or hot stamping | ||

Tensile Strength | 155N | ||

Application | Trucks, trailers, freight containers, logistics transportation, etc | ||

Packing | 100pcs / Bag 5000 pcs/ Box | ||

MOQ | 1000 PCS | ||

Primary Industry Application Scenarios

The versatility and reliability of industrial plastic tamper-evident seals make them critical assets in safeguarding product integrity across a vast spectrum of sectors.

Pharmaceuticals and Medical Devices: Ensuring the sterility and safety of products is non-negotiable. Seals are used on medicine bottles, sample kits, diagnostic equipment, and shipment containers to comply with strict Good Manufacturing Practice (GMP) and regulatory requirements, providing visible proof that products have not been compromised.

Food and Beverage Production: Essential for confirming that food products remain untampered with from the processing plant to the consumer. Applied to packaging seals, bottle caps, and bulk ingredient containers, they protect against contamination and adulteration, supporting food safety standards like HACCP and FSMA.

Electronics and High-Value Components: Used to seal boxes containing sensitive electronics, semiconductors, or proprietary hardware. The tamper evidence deters theft, prevents the swapping of components, and assures customers they are receiving genuine, unopened products.

Logistics, Transportation, and Cargo Security: Applied to the doors of trailers, air cargo containers, and warehouse storage units. These seals provide a immediate visual check for unauthorized entry during transit and storage, forming a key part of cargo security protocols and loss prevention programs.

Chemical, Agrochem, and Industrial Supplies: Securing drums, totes, and containers holding hazardous or valuable materials. They prevent unauthorized access, accidental exposure, and product dilution, ensuring safety and maintaining material quality.

Government, Legal, and Forensics: Used for sealing evidence bags, ballot boxes, confidential documents, and sensitive equipment, where maintaining an indisputable chain of custody is legally mandatory.

Factory picture

Frequently Asked Questions (FAQ)

1. How do I select the right type of plastic tamper-evident seal for my specific packaging?

Selection is based on several factors: the material and surface of your package (plastic, glass, cardboard), the required level of security, environmental conditions (temperature, moisture), and your production line speed. We offer consultation services where our experts analyze your application—whether it's a bottle neck, a cardboard flap, or a drum lid—and recommend the optimal seal type, adhesive, and size to ensure both reliable performance and effective tamper evidence.2. Can your customized serialized seals be integrated with our existing Enterprise Resource Planning (ERP) or track-and-trace software?

Absolutely. This is a core strength of our offering. We can produce seals with sequentially numbered codes in human-readable and machine-scannable formats (like QR codes). The numbering sequence can be tailored to your specification and delivered with a corresponding data file. This allows you to associate each seal number with a specific batch, order, or shipment in your software system, enabling real-time verification and creating a powerful digital audit trail from production to end-user.3. Are the materials used in your plastic seals compliant with international safety and environmental regulations, such as FDA, EU RoHS, or REACH?

Yes, regulatory compliance is integral to our manufacturing. We produce seals using materials that are fully compliant with relevant global standards. For food and pharmaceutical contact, we use FDA-compliant materials and adhesives. Our products also adhere to RoHS and REACH directives regarding restricted substances.