Plastic Lock Seal Containers

01. Plastic seals have the advantages of low cost, high strength, good adhesion, etc., and can also be bent at will on demand, easy to operate, and beautiful arc.

02. The plastic seal is made of PP+PE raw material, which has the characteristics of acid resistance, corrosion resistance and insulation, not easy to age and strong bearing capacity. It can maintain the same shape in the environment from minus 45 degrees to above 50 degrees.

03. It can be tightened and adjusted at will during sealing. And will not cause pollution to the environment.

Plastic Lock Seal Containers are generally available in red, yellow, blue and green, and we can also customize colors for our customers.

Plastic Lock Seal Straps represent a fundamental advancement in physical asset management and wire containment systems. As a specialized industrial component, this product transcends its basic form to become an integral part of systematic workflow organization. Designed for durability and repetitive use in demanding environments, these straps provide a reliable method for securing and bundling wires, cables, hoses, and linear materials across numerous sectors. By replacing temporary or inadequate fastening methods, they introduce uniformity, safety, and efficiency into daily operations, serving as a critical tool for maintenance teams, engineers, and facility managers in B2B settings where order and reliability are paramount.

Core Design & Engineering Features

1. Precision Locking Mechanism for Maximum Security

At the heart of the product's functionality is its reliable, self-contained locking design, engineered for one-time or reusable application.

Hook-and-Tooth Engagement System: The strap system comprises two key parts: a square locking head incorporating a molded, hook-shaped elastic buckle, and a flexible serrated strap body. When the serrated end is inserted through the head and tensioned, the internal hook mechanism engages the teeth with positive locking action, creating a secure, vibration-resistant hold that prevents accidental loosening.

Adjustable Loop Sizing: Unlike fixed-diameter closures, this design allows for the creation of a perfectly sized loop. The strap can be drawn tight to form a custom fit around any bundle diameter, from individual wires to large cable clusters, ensuring snug and secure containment without excessive pressure that could damage sensitive cable jackets or internal conductors.

High-Strength Polymer Construction: Manufactured from engineered plastics such as nylon or reinforced polypropylene, these plastic lock seals offer an optimal balance of tensile strength, flexibility, and environmental resistance. The materials are selected for their durability against UV exposure, temperature fluctuations, and common industrial chemicals.

2. Functional Advantages for Operational Efficiency

The design prioritizes user efficiency and integration into professional workflows, offering tangible benefits beyond simple fastening.

Rapid, Tool-Free Application: The intuitive "thread-and-pull" action enables quick installation without specialized tools, significantly reducing the time required for large-scale bundling projects or on-the-spot repairs. This efficiency is crucial in production environments or during time-sensitive maintenance windows.

Integrated Identification & Tracking Platform: The broad, flat surface of the square plastic locking head provides an ideal area for permanent marking. It can be customized with laser-etched serial numbers, barcodes, QR codes, or company logos, facilitating asset identification, inventory control, and integration into digital maintenance management systems (CMMS).

Versatility in Configurations: While many applications utilize the strap as a one-time use, tamper-evident seal (where removal requires cutting), specific designs can incorporate a releasable mechanism. This allows for non-destructive removal and reuse, ideal for applications requiring regular reconfiguration, such as prototype development, temporary installations, or adjustable equipment setups.

3. Enhancing Safety & System Reliability

Proper cable management directly contributes to overall operational safety and the longevity of electrical and mechanical systems.

Hazard Mitigation: By neatly containing loose lines, these straps effectively eliminate trip hazards, prevent snagging on moving machinery, and reduce the risk of accidental disconnection or damage caused by tangled cables.

Optimized Performance & Maintenance: Organized bundles improve airflow around cables, reducing heat buildup that can degrade insulation and performance. A clean, logical layout also dramatically simplifies visual inspections, troubleshooting, and scheduled maintenance, leading to lower downtime and operational costs.

Compliance with Industry Standards: The use of standardized, high-quality fastening solutions helps organizations comply with internal safety protocols and external regulations in industries like manufacturing, energy, and telecommunications, where orderly cable management is often audited.

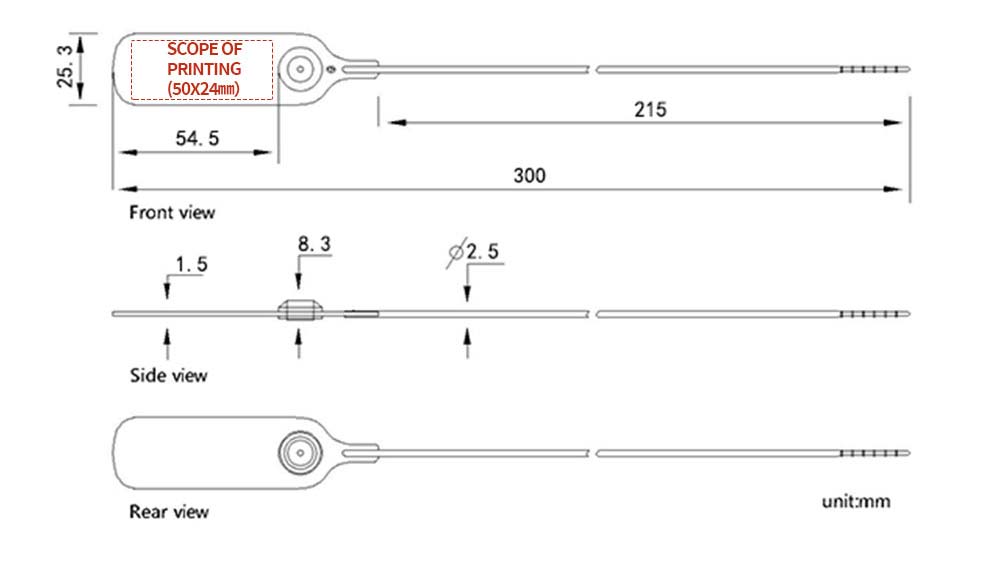

Specification of Plastic Lock Seal Containers

Material | PP or PE |

Colour | Red,green,white,yellow,blue and etc |

Lock size | 54x25mm |

Diameter | 2.5mm |

Length | 300mm or any length as required |

Printing | Hot stamping or laser etch of logos, bar codes and codes |

Package | 100ocs per bag, 50bag per carton |

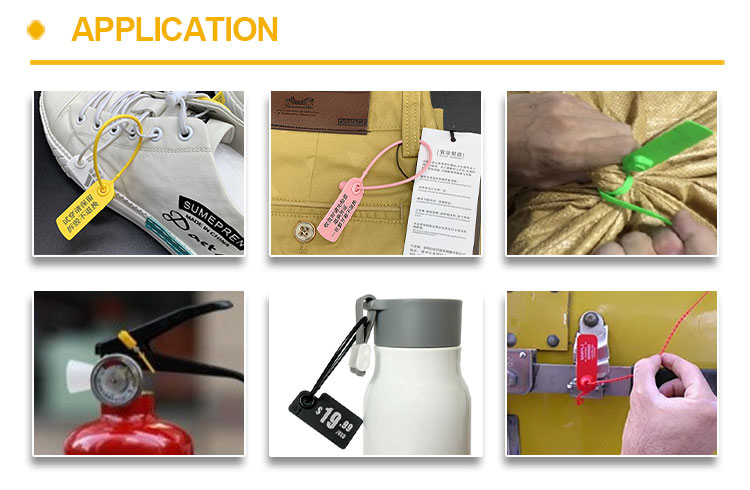

Application | Dispoable plastic seal is suitable for container shipping, tanker transportation, truck freight, trailer freight and so on |

Primary Industrial & Commercial Applications

Plastic Lock Seal Straps are ubiquitous in environments requiring organized, secure, and identifiable containment of linear components.

Information Technology & Data Center Management: Essential for rack and cable management within server cabinets, networking closets, and telecom rooms. They organize data and power cables, ensuring proper airflow, ease of traceability, and a professional, maintainable infrastructure.

Industrial Automation & Machinery: Used to secure wiring harnesses, pneumatic tubes, and sensor cables on factory automation equipment, CNC machines, and robotic work cells. This protects cables from abrasion against moving parts and maintains clean lines for safety and serviceability.

Automotive, Aerospace & Transportation: Applied in vehicle and aircraft assembly for securing pre-formed wire looms and fluid lines along chassis and within panels, ensuring they withstand vibration and environmental stress throughout the product's lifecycle.

Energy, Utilities & Electrical Distribution: Employed in electrical panels, control cabinets, and substations for bundling power and control cables. The lock heads serve as perfect points for applying circuit identification labels, crucial for safety and operational clarity.

Facilities Management & Construction: Used for temporary or permanent securing of extension cords, temporary lighting, conduit runs, and equipment on construction sites or within building maintenance, promoting a tidy and safe worksite.

Logistics & Warehouse Operations: Useful for securing coiled hoses, bundling tools, or organizing cables on forklifts and other material handling equipment, contributing to general warehouse organization and safety.

Frequently Asked Questions (FAQ)

1.Can these straps be customized with specific colors and permanent markings for our asset tracking system?

Yes, as a professional manufacturer, we offer extensive customization to support your operational needs. We can produce straps in a wide array of standard or custom Pantone-matched colors for color-coding applications. Furthermore, we provide high-contrast laser marking services to permanently etch sequential numbers, asset codes, barcodes, or corporate logos directly onto the locking head. This facilitates seamless integration into your asset tracking and management software.

2. Are the materials used environmentally compliant and suitable for use in sensitive environments (e.g., food processing, cleanrooms)?

We prioritize material compliance. Our standard products are manufactured using plastics that comply with international RoHS and REACH directives. For sensitive environments, we offer specific lines made from FDA-compliant or antistatic materials. We can guide you to the most appropriate, chemically inert, and low-particulate shedding material for applications in food and beverage, pharmaceutical, or electronics manufacturing settings.

3. What is the difference between a one-time-use and a releasable model? Which is more suitable for our application?

The standard model is designed as a permanent, one-time-use lock seal. Once engaged and tensioned, it cannot be opened without cutting the strap, providing a clear indication of tampering—ideal for security sealing, final installations, or safety-critical applications. The releasable model features a integrated tab or lever that disengages the internal hook, allowing the strap to be unlocked, adjusted, and re-tightened.